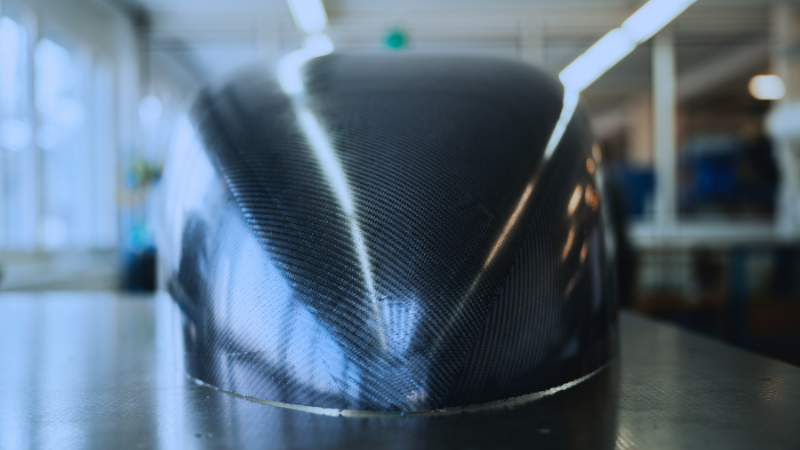

We’re producing first composite component using autoclave technology from a 3D-printed mold

Connova Group has teamed up with the two partner companies Caracol (IT) and Formbar (CH) to investigate the possibilities of a 3D printed mold in a joint R&D project. For this purpose, Connova Group has provided 3D data of the nose structure from an ongoing drone project. Based on this data Caracol then engineered and printed the mold on the HERON AM platform – an innovative, modular 3D printing system for large-scale applications that uses polymer and composite pellets. The innovation lies exactly in this choice of materials, which allows the use of this mold in an autoclave at a temperature of 130°C and a pressure of 6 bar.

Before the mold could be used at Connova Group, the corresponding molding surface had to be mechanically machined by the company Formbar, which has large and still precise CNC milling machines available for this purpose. Only then were the composite specialists at Connova Group able to manufacture the component by means of the well-known prepreg/autoclave process. For the very first component from a 3D printed mold, the part looks surprisingly good! And you can currently visit it at JEC World 2024 in Paris at the Caracol stand!