Interview about innovative development processes for hydrogen technologies with Thomas Leschik, CEO of Connova Deutschland GmbH

Mr. Leschik, the Connova Group is known for its pioneering work in the field of composite materials. What challenges do you currently see in the hydrogen industry?

Thomas Leschik: The biggest challenge is certainly time. The development of hydrogen technologies, such as pressure tanks or pumps, is time-consuming. Currently, we are looking at development times of three to five years, followed by another five years to ramp up production. These time frames are too long to meet the climate targets in Europe quickly enough.

How does the Connova Group handle this? You mentioned ways to shorten these development times.

Thomas Leschik: Exactly, our approach is to consider mass production already in the prototype phase. We develop prototypes in such a way that they can be reproduced under real production conditions. This means that we use multiple tools and material batches from the start to accurately measure and control quality and tolerances. This ultimately saves time and costs when the customer enters series production.

How does this affect the quality of the end products?

Thomas Leschik: By controlling the entire process and focusing on quality from the start, we can make more precise statements about component quality. Our customers receive not only the first prototype but also reliable statements about feasible tolerances and expected qualities. This leads to a faster start-up of stable series production without major surprises.

What about the current safety standards, especially for hydrogen pressure tanks?

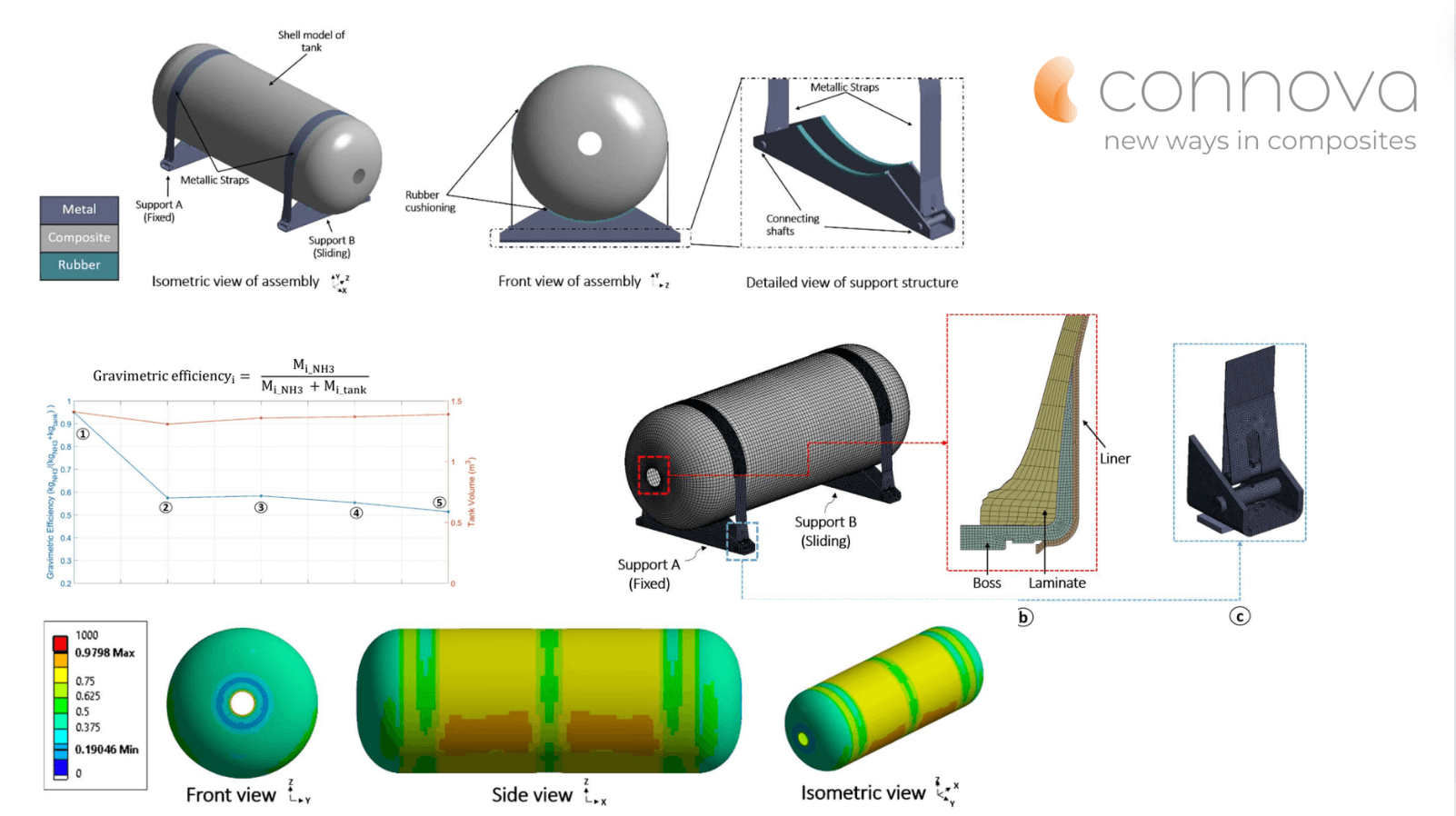

Thomas Leschik: European standards currently require a hydrogen pressure tank to withstand a burst pressure of 1652bar at an operating pressure of 700bar. These standards are over a century old and do not take into account advances in materials science and production technology. At Connova Group, we rely on the latest simulation methods and materials knowledge, which allows us to reduce safety factors without compromising safety by maximizing the use of theoretical material properties in real manufacturing. The result is lighter and more efficient components.

What can your customers expect from Connova Group in the future?

Thomas Leschik: Our customers can expect continuous innovation and improvement of production processes. We are in the process of expanding our capabilities as a “composite series manufacturer with a focus on robust precision” and broadening our approach to controlled & efficient material processing to avoid unnecessary weight and costs. Our long-term series productions and partnerships with world leaders in various industries testify to our commitment and reliability.

Thank you, Mr. Leschik, for these insights into the exciting world of lightweight components and hydrogen technology.

Thomas Leschik: Thank you. It is an exciting time, and we are proud to be at the forefront of these developments and to drive the hydrogen industry forward.

Interested in further insights? Download the full presentation slides from Thomas Leschik’s lecture at the Dresden Lightweight Construction Symposium here and learn more about our innovative approaches in hydrogen technology and composite processing.

Download Presentation Slides Now