KNOW-HOW

15 Jahre Erfahrung in der Raumfahrt

15 Jahre Erfahrung in der Raumfahrt

Ultra-rigid structures for the harsh conditions in space

Project-specific solutions according to customer requirements

Connova Group has also been active in the aerospace industry for over 15 years. With our lightweight and highly rigid composite components, we increase the payload capacity of launch vehicles and build structures for particularly lightweight satellites and spacecraft. We have a broad space heritage and convince with project-specific solutions.

We have many years of experience in the development and production of space structures made from composite or titanium components. Regardless of whether particularly high mechanical or special thermo-mechanical requirements are needed for the harsh conditions in space – our engineers already know the solution or develop it together with the customer.

As specialists for composite solutions in the aerospace industry, we offer a comprehensive portfolio of services: From consulting and product development in the aerospace sector to the design and analysis of aerospace components and the optimization of aerospace systems.

With many years of expertise in the production of high-performance aerospace composites, our specialists ensure the most effective manufacturing method for your aerospace product, always maintaining the highest quality standards and reliable delivery.

We offer a wide range of CNC services specifically for model making, mold making and the final machining of composite components in the aerospace industry, always with a 100% guarantee of accuracy.

We offer a comprehensive range of machining and support services that can serve both as an integral part of your aerospace composite component manufacturing process and as complementary support for your own manufacturing.

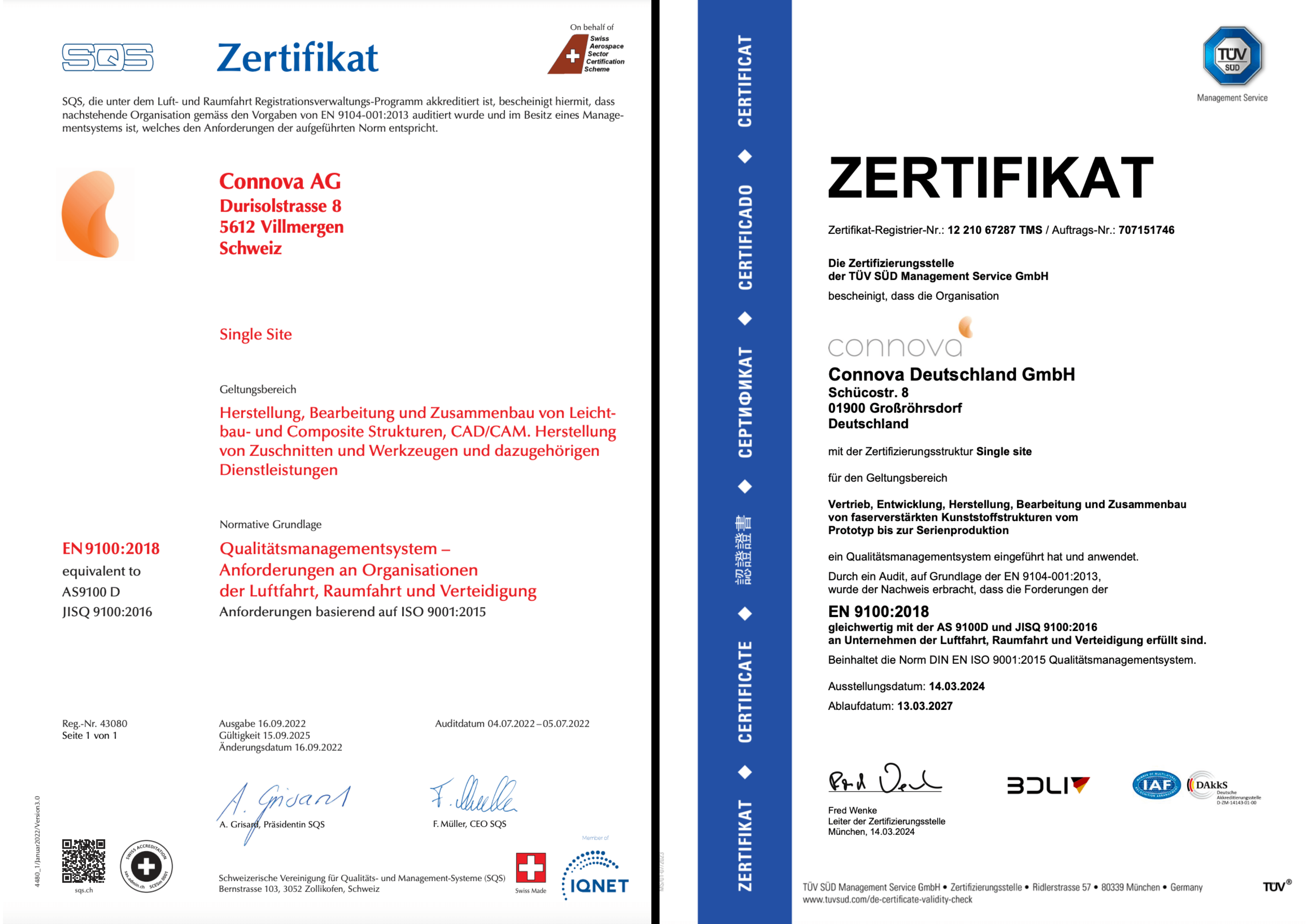

In addition to our standard ISO 9001 certification, we proudly maintain our higher level EN9100 quality management certification for the aerospace industry. We ensure controlled, measurable quality from material procurement to final product delivery. With our high-precision testing equipment, we meet the highest industry standards. Trust us when it comes to precision and consistent quality assurance.

Connova Group was responsible for the development of the manufacturing processes and the production of four complete landing legs for a demonstrator of a future launch vehicle as part of the Themis project.

The project, commissioned by Almatech and ArianeGroup, aims to develop technologies for cost-efficient, reusable rockets that are to be put into operation after 2030 as the successor to Ariane 6

With great expertise gained from numerous projects in the field of lightweight construction over several decades, we are ready to realize your visions. Contact us for a professional consultation where we can discuss together how we can act as your potential partner. Our consultation service is of course free of charge and without any obligation for you.