For rotation-symmetric items – high mechanical performance, economical and scalable

Vacuum Infusion Technology

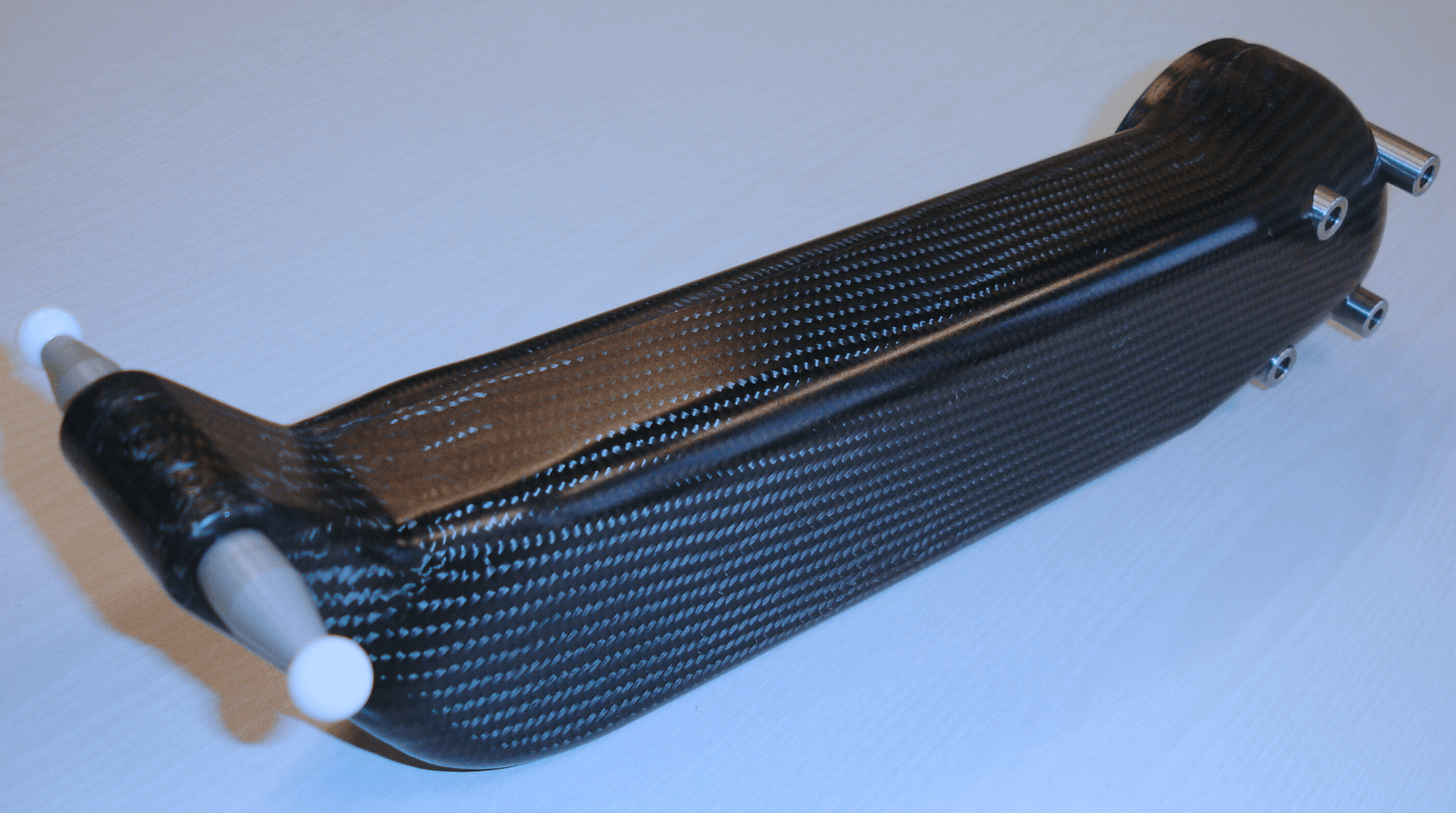

The vacuum infusion is ideal for single parts with large dimensions and for small series. The process allows for high quality and perfect surfaces on one side.

Advantages of the vacuum infusion process are:

- Inexpensive process for large components

- Process requires just simple equipment

- High fibre volume content

- High surface quality on one side

In the infusion process, similar to the RTM process, the dry reinforcement material is placed in a mould which has been coated with release agent upfront. The entire structure is then evacuated and compressed under a vacuum bag and the polymer matrix is sucked-in (impregnation). The curing can take place at room temperature and may take a few hours. The process can be accelerated by elevated temperatures. In order to increase the temperature resistance of the components, they are typically post-tempered at higher temperature in an oven after demoulding.

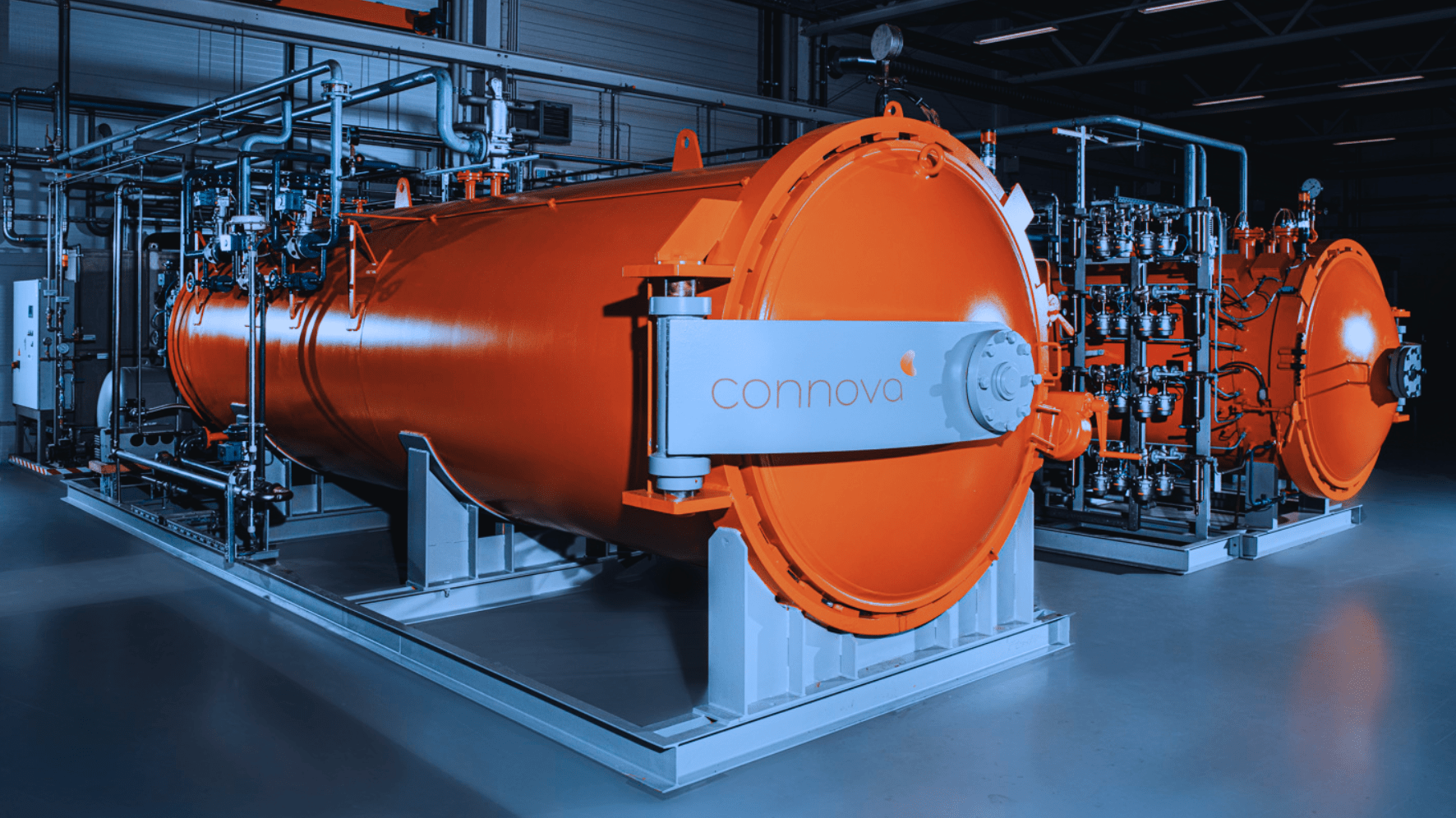

Connova Group has the know-how and the means for the vacuum infusion process:

- Infusion set-up

- Vacuum-tight moulds

- Clean and controlled lamination rooms to prevent external contamination

Typical applications of the vacuum infusion process are:

- In yachting: boat hulls, structural components

- In automotive: body panels, components of the driver’s cell

- In mechanics covers, cladding, large mould for composite components

- In energy supply: blades for wind turbines