For rotation-symmetric items – high mechanical performance, economical and scalable

RTM Technology (Resin Transfer Moulding)

The RTM process allows high reproducibility and a short cycle time. It is particularly suitable for geometrically complex components with good surface quality on all sides and for large quantities.

Advantages of the RTM process are:

- Precisely definable fibre orientation

- High fibre volume content

- High surface quality all-around

- Exact geometry all-around

- High temperature resistance (high glass transition temperature Tg)

- Short cycle times

In the RTM process, the dry reinforcement material is placed in the mould. After closing the mould, the matrix (resin with hardener) is injected by external pressure and/or sucked-in by vacuum (impregnation). In case of complex components, it is feasible to work with preformed sub-elements, co-called preforms. Mainly mats, braids and fabrics are used, which are pre-bond to each other by a thermoplastic binder activated by heat. The curing time of the component ranges from 15 to 90 minutes depending on the type of material and the size and esp. the mass of the items. The component is then demoulded and processed further.

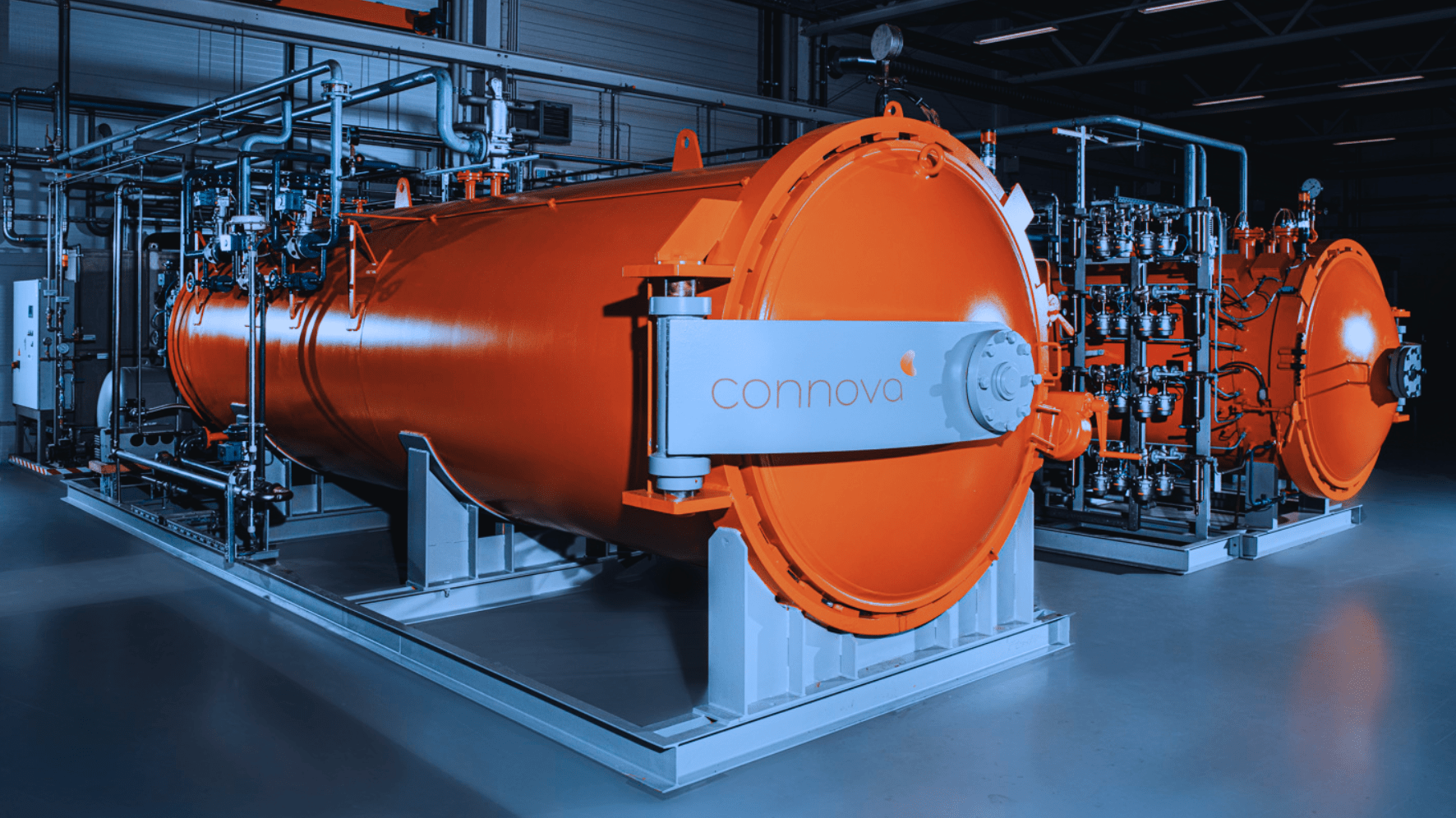

Connova Group has the know-how and the means for the RTM process:

- High-quality, temperature and pressure-resistant moulds (usually made of aluminium or steel)

- Press or locking system for keeping the mould closed under internal pressure

- Clean and controlled lamination rooms to prevent external contamination

- Precise mixing and dosing system

- Separate preforming stations

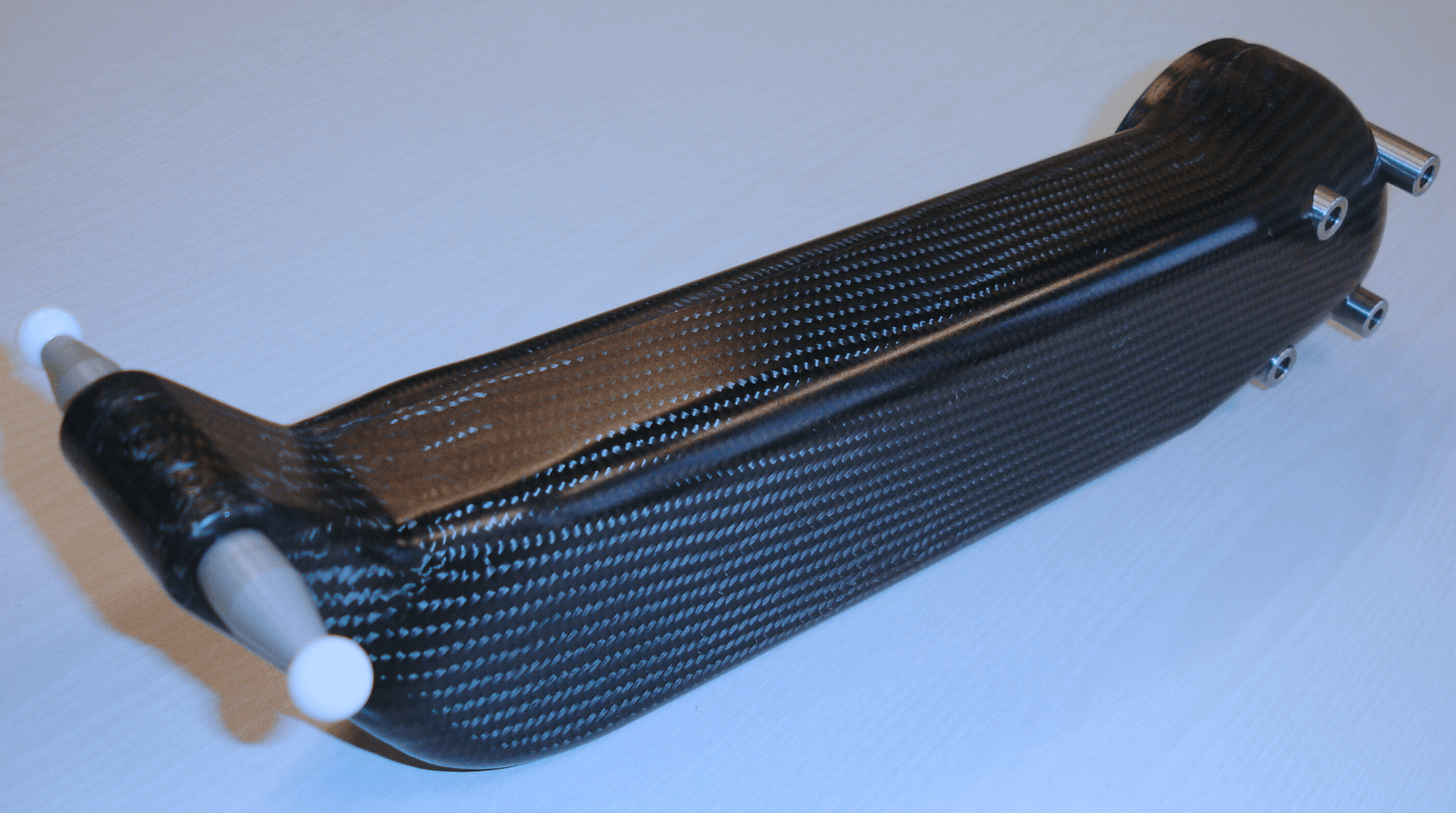

Typical applications of the RTM technology are:

- In aviation: control levers, rudders, fairing parts

- In automotive: tailgates, spoilers, decorative covers

- In mechanics: robotic arms, high-speed machine parts, fitting

- In medical: prostheses (aids outside the body)

- In sports & leisure: bicycle frames, boat paddles