For rotation-symmetric items – high mechanical performance, economical and scalable

Prepreg Composite

Exploring the Pioneering World of Prepreg Composite Technology with Connova Group

In the realm of high-performance materials, few innovations offer as much potential as prepreg composite technology. Spearheaded by Connova Group, this cutting-edge technology leverages pre-impregnated fibers encapsulated in a partially cured polymer matrix to craft components that are not only lightweight but also exceptionally strong and resilient.

What is Prepreg Composite?

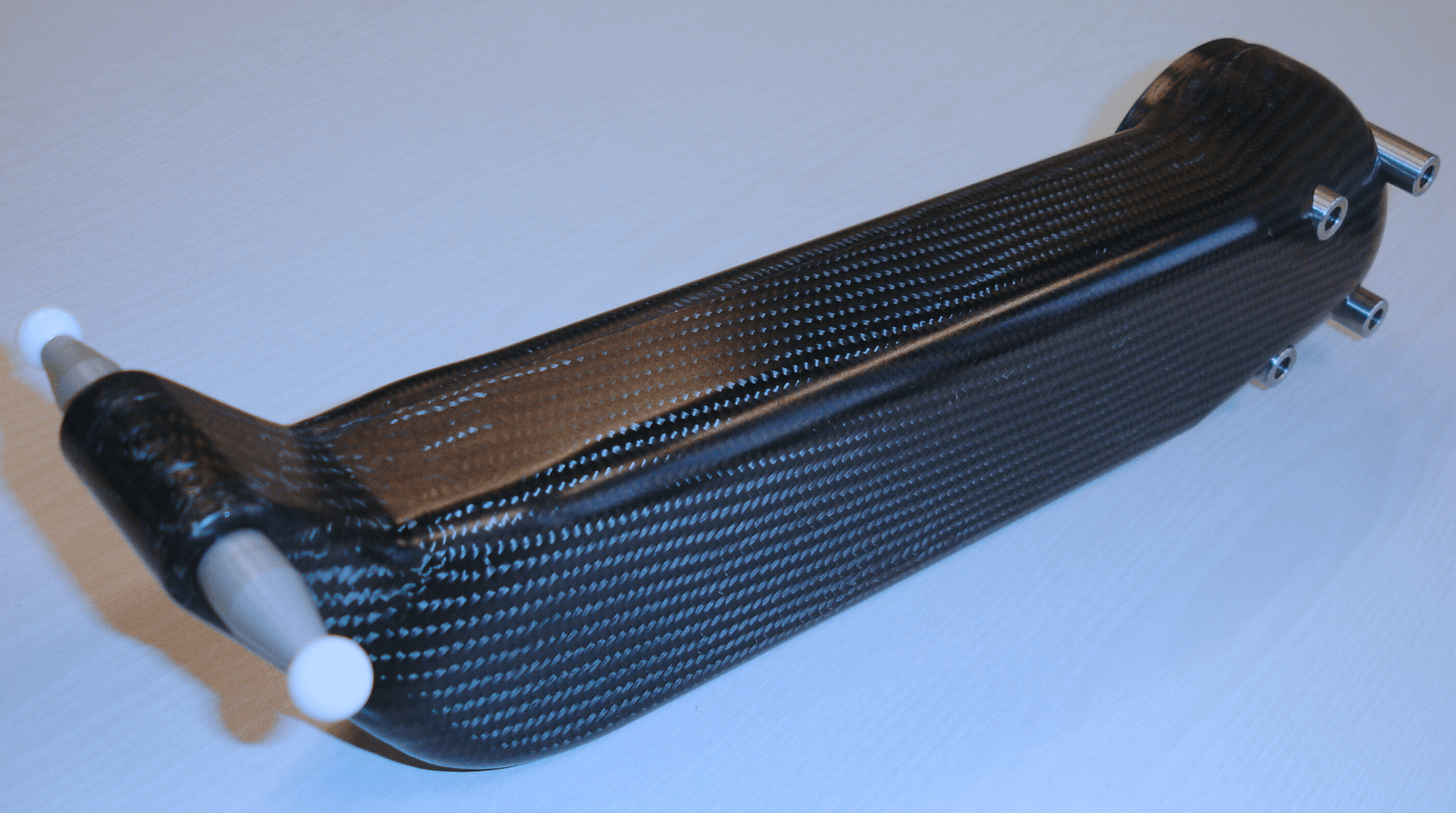

Prepreg, short for “pre-impregnated” fibers, consists of continuous fibers—either unidirectional, woven, or non-woven—saturated in a thermoset polymer matrix that hasn’t fully hardened. This unique configuration allows for precise control over the fiber orientation and volume content, yielding materials with low porosity, high surface quality, and superb temperature resistance.

The Process and Benefits of Prepreg Autoclave Technology

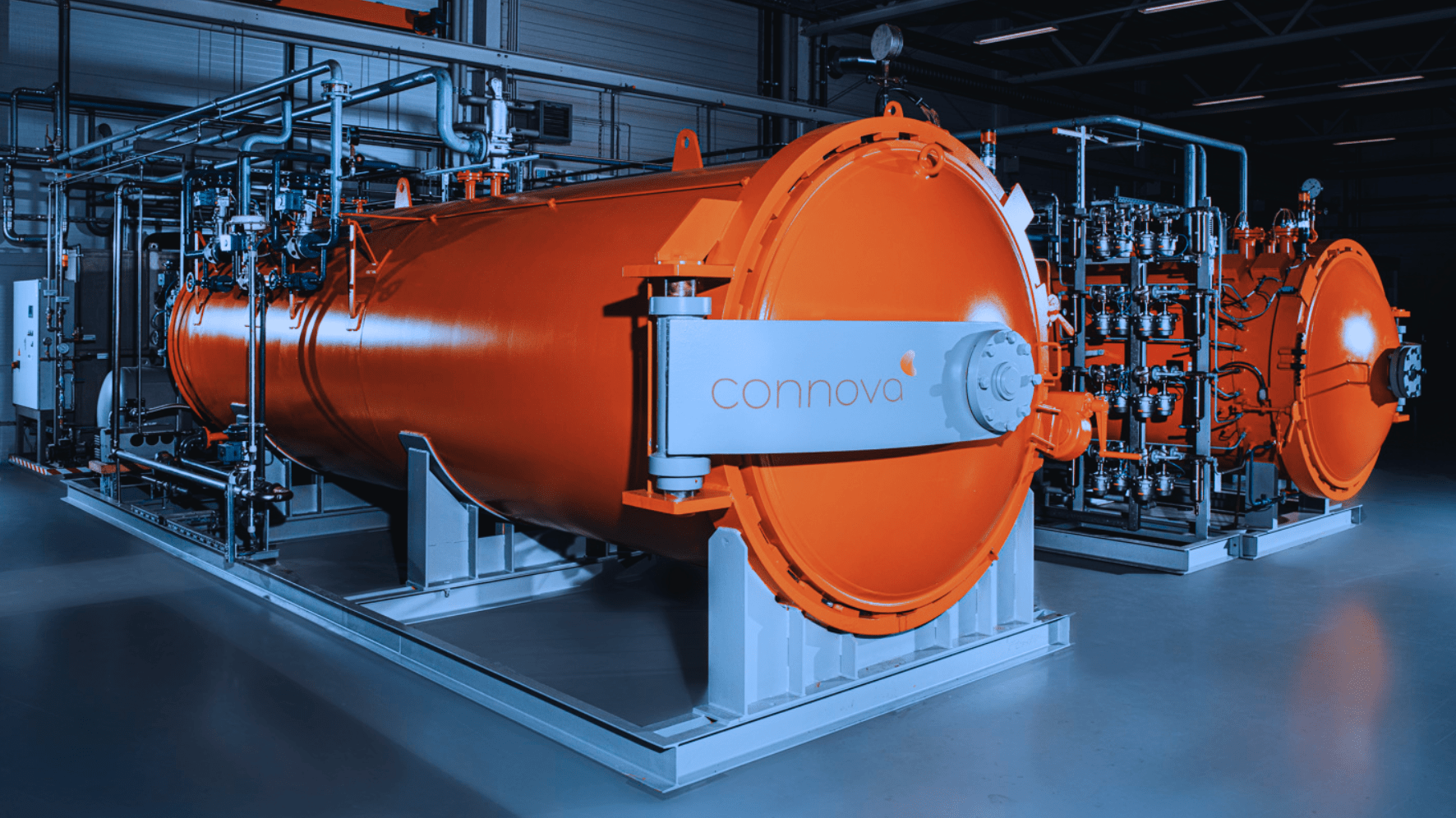

Connova Group utilizes an advanced autoclave process to cure these materials under high pressure and temperature, a method that typically spans 4 to 7 hours depending on the material type and component size. The autoclave technology not only facilitates a well-defined fiber orientation—crucial for achieving the desired mechanical properties such as elasticity or rigidity—but also ensures a high-quality, consistent material with excellent force transmission from fiber to fiber.

This process offers multiple advantages:

- Precision: Components are layered in a mold in a precise orientation to create a defined laminate structure.

- Quality: The technology ensures high surface quality and low porosity, resulting in stronger, more reliable components.

- Performance: High temperature resistance means components can withstand extreme conditions, making them ideal for demanding applications.

Applications Across Industries

Connova Group’s prepreg autoclave technology finds applications in various high-demand sectors. From aerospace, where it’s used for fuselage and wing structures, to automotive racing, where the material’s strength-to-weight ratio offers significant performance benefits. Additionally, the technology is employed in the manufacturing of high-performance parts for yachting, space exploration, and even medical devices like X-ray transparent patient beds.

Expertise and Infrastructure

Connova Group has established a robust infrastructure to support its advanced manufacturing processes. This includes temperature-resistant molds, computer-controlled autoclaves that can accommodate large components, and CNC machining centers for precise finishing. Their facilities also boast controlled environments to prevent any contamination during the laminating process, ensuring the highest quality standards are met.

Commitment to Innovation

Connova doesn’t just manufacture components; they are deeply involved in the engineering and development of custom solutions tailored to meet the specific needs of their clients. With decades of experience and a commitment to quality evidenced by ISO EN9100 and EN9001 certifications, Connova is a leader in the composites industry, continually pushing the boundaries of what’s possible with materials science.

Looking Ahead

As industries continue to seek lighter, more efficient materials that do not compromise on strength or integrity, Connova Group’s expertise in prepreg autoclave technology positions them at the forefront of the composites field. With ongoing investments in research and development, Connova remains dedicated to advancing these materials for future applications, promising new ways to innovate across sectors as diverse as aerospace, automotive, and beyond.

Through their comprehensive approach from conception to production, Connova ensures that each project not only meets but exceeds the exacting demands of modern engineering challenges, demonstrating the transformative potential of prepreg composites in shaping the future of material science.