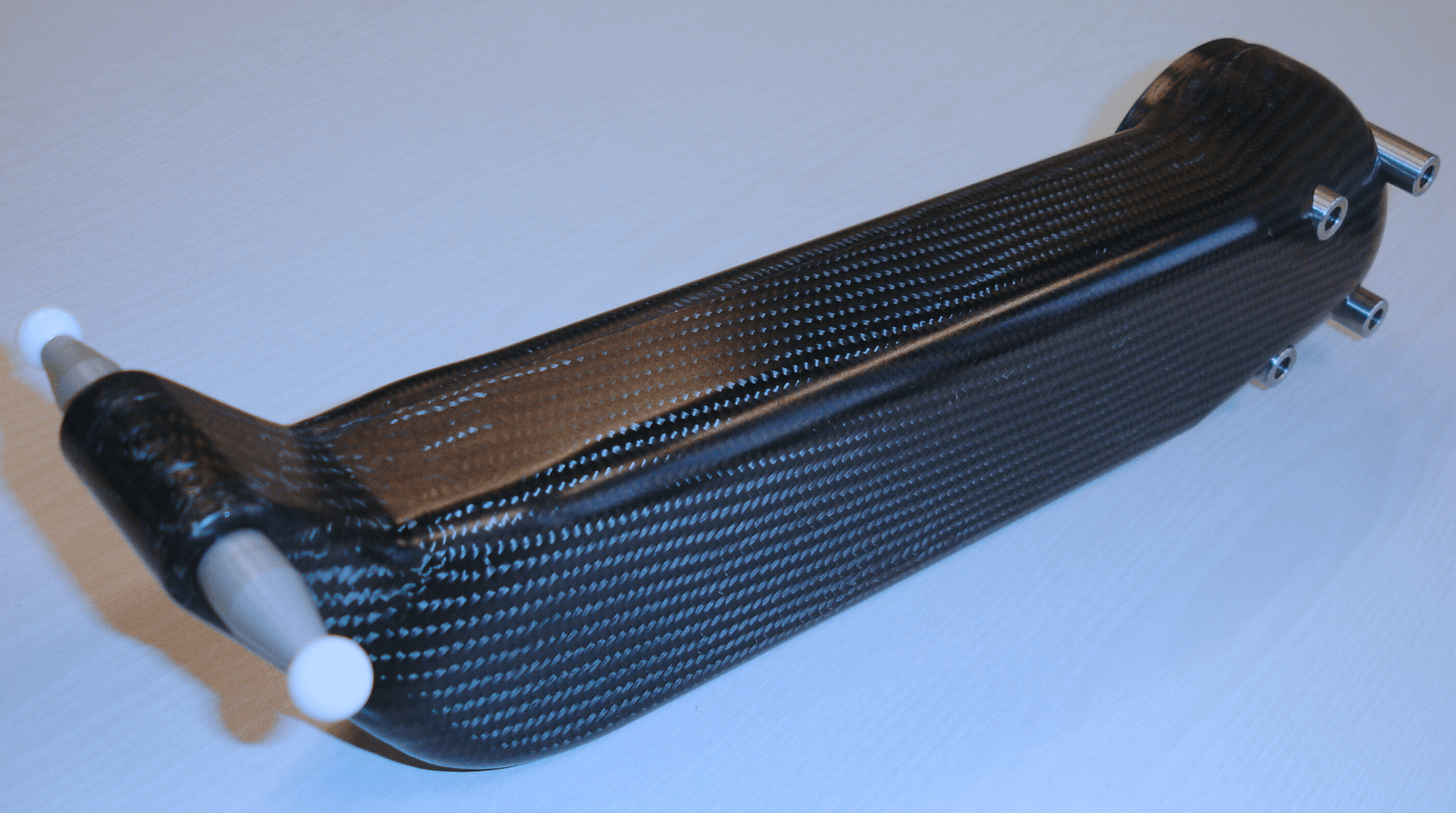

For rotation-symmetric items – high mechanical performance, economical and scalable

Prepreg Autoclave Technology

The fibre orientation gives the components the desired strength and stiffness. The hardened polymer matrix holds the fibres together in the final component and leads to optimal force transmission from fibre to fibre. This results in a consistently high material quality and ideal technical properties.

Advantages of prepreg autoclave technology are:

- Precisely definable fibre

- Ideal fibre volume content

- Low porosity

- High surface quality

- High temperature resistance (high glass transition temperature Tg)

“Prepreg” stands for “pre-impregnated fibres”. Prepreg consists of continuous fibres and a not-yet-fully-hardened, mostly thermo-set polymer matrix. The fibres can be present as a unidirectional layer, as a woven or non-woven fabric.

Prepregs are precisely cut on the cutter and placed in layers in the defined sequence and orientation into a mould until the defined laminate structure is created. A well-defined fibre orientation gives the components the desired properties such as elasticity or rigidity.

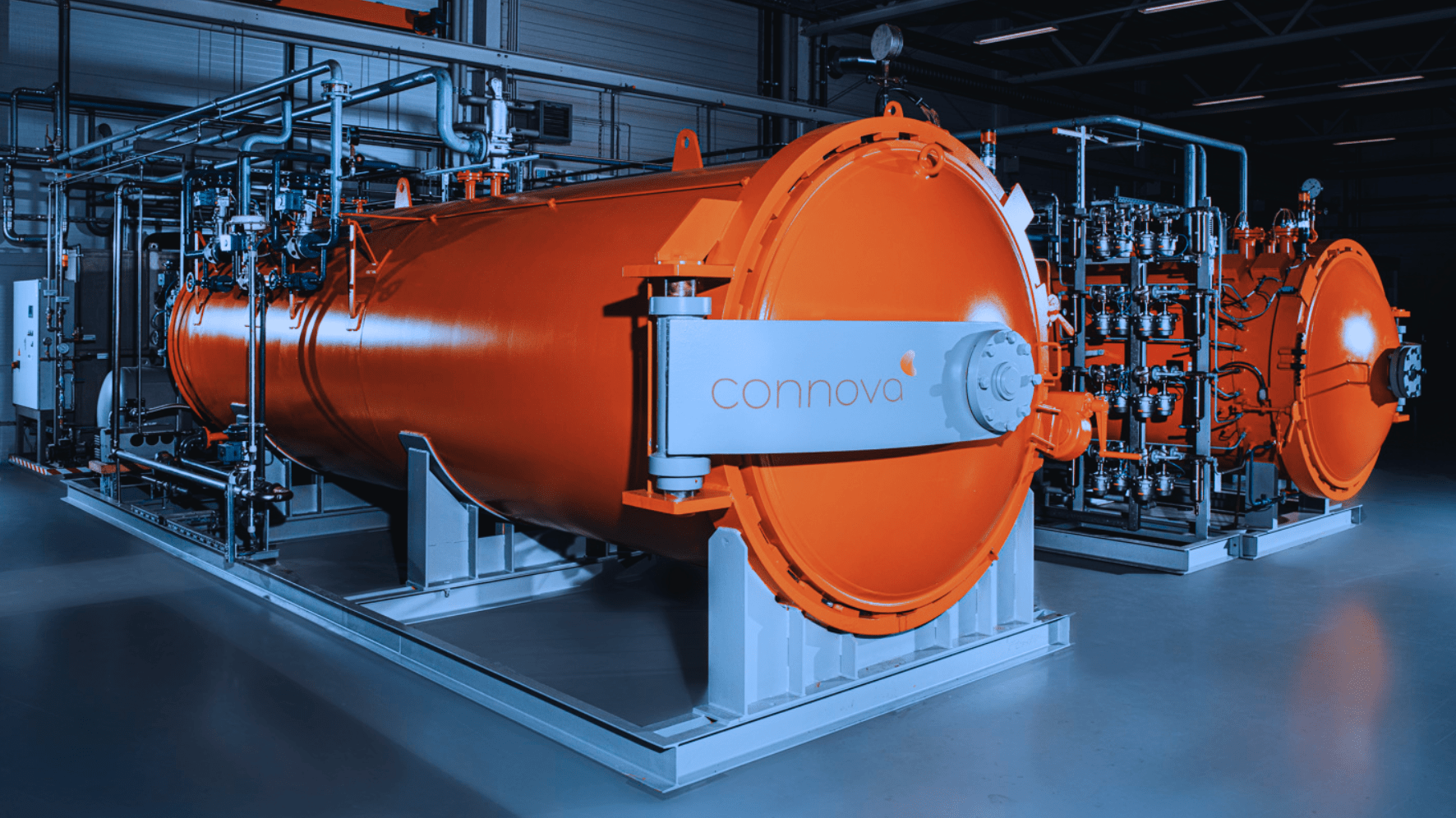

The mould including the component is then evacuated in a temperature-resistant foil bag and cured under pressure and heat in a numerically controlled autoclave. This takes typically 4 to 7 hours depending on the type of material and the size and quantity of the items in the autoclave. The component is then cooled in a controlled manner, removed from the mould (demoulding) and processed further.

Connova Group has the know-how and the means for prepreg autoclave technology:

- Temperature-resistant and precise moulds and tools

- Controlled deep-freeze cells for safe storage of the uncured prepregs

- Computer-controlled autoclaves for components up to 4m in length

- CNC machining centres for accurate and efficient milling, trimming, cutting

- Clean and climate-controlled laminating rooms to prevent external contamination

Typical applications of prepreg autoclave technology are:

- In space: primary structures, solar panels, instrument panels

- In aviation: fuselage and wing structures, interior fittings, cladding, rotor blades

- In racing: chassis, wheel suspension, aerodynamic structures, fairings

- In yachting: masts, hull structures of high-performance ships

- In mechanics: robotic arms, high-speed machine parts, thermostable machine tables

- In medical: X-ray transparent patient beds, prostheses (walking aids, outside the body)

- In metrology: thermally stable equipment carriers, optical benches