Fibre-reinforced components are not easy to handle.

Mould and Tool Making

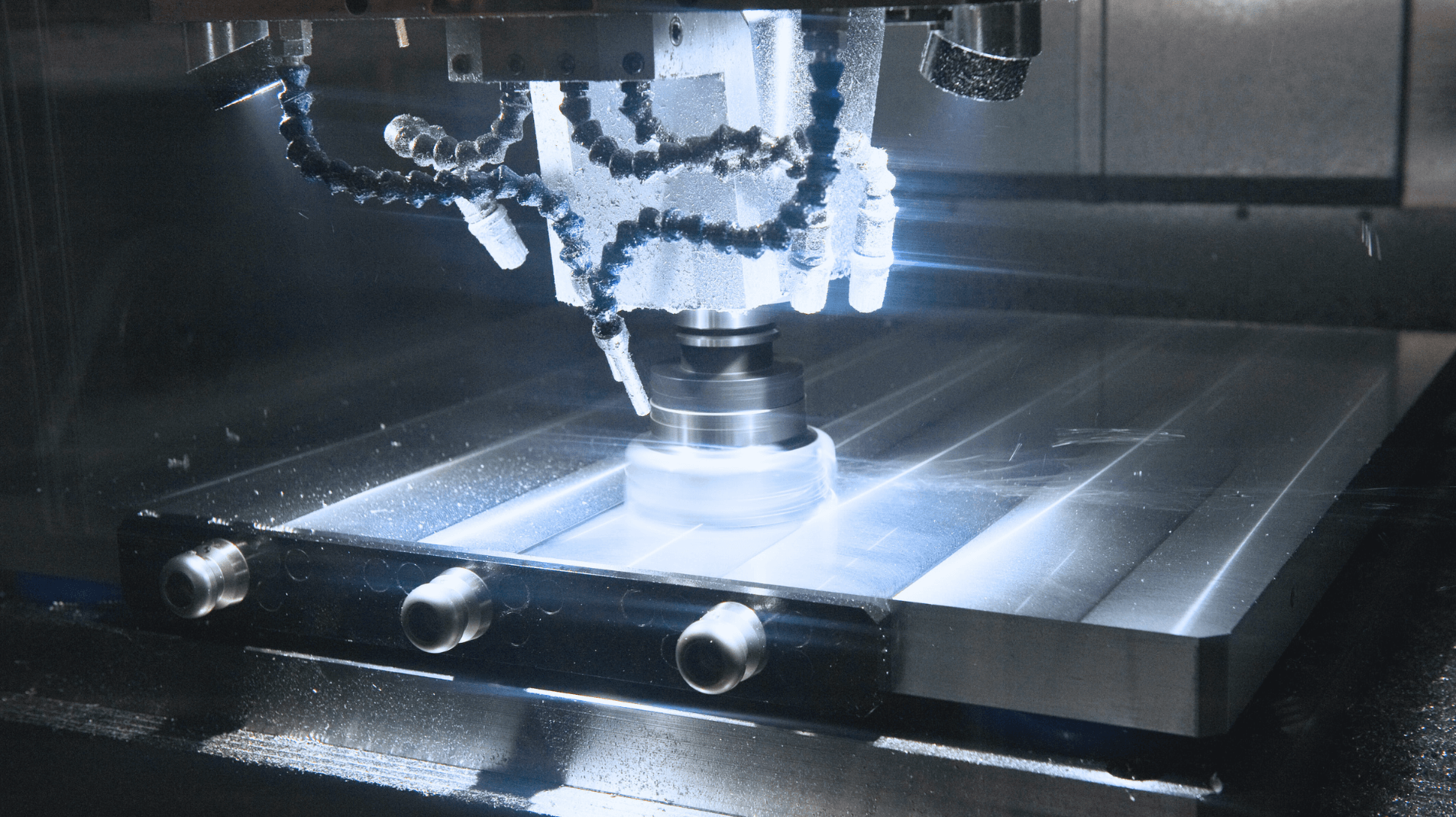

Moulds, tools, and master models from Connova Group stand for maximum precision and versatility – whether as a separate service for your own use or as part of our composites production. With state-of-the-art CNC machining centres and comprehensive services, we guarantee you first-class quality.

We offer following types of tools:

- Lamination moulds for composite

- Master models

- Design models

- Functional models

- Prototypes

- Jigs and Fixtures (e.g., for adhesive bonding, CNC milling, inspection, testing, etc.)

We use our milling machines to produce dimensionally accurate positives (master models) as well as directly negatives (moulds). Our CNC experts work efficiently at the centrally located CAD and CAM workstations and continuously monitor the CNC machining shop from their working place.

Negative Moulds

By means of a positive master model (a one-to-one copy of the component to be manufactured), our experienced model builders laminate or cast exact negative moulds. The processes and materials used to manufacture the moulds are selected and adapted according to your needs.

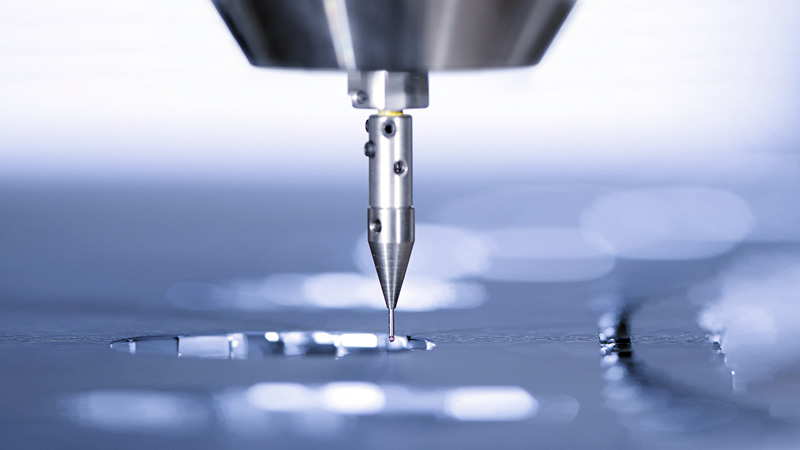

Surface finish

Our experts grind, seal and polish the surfaces to achieve the specified surface quality. The Connova Group finish guarantees a fast and reliable demoulding of the finished parts after curing.