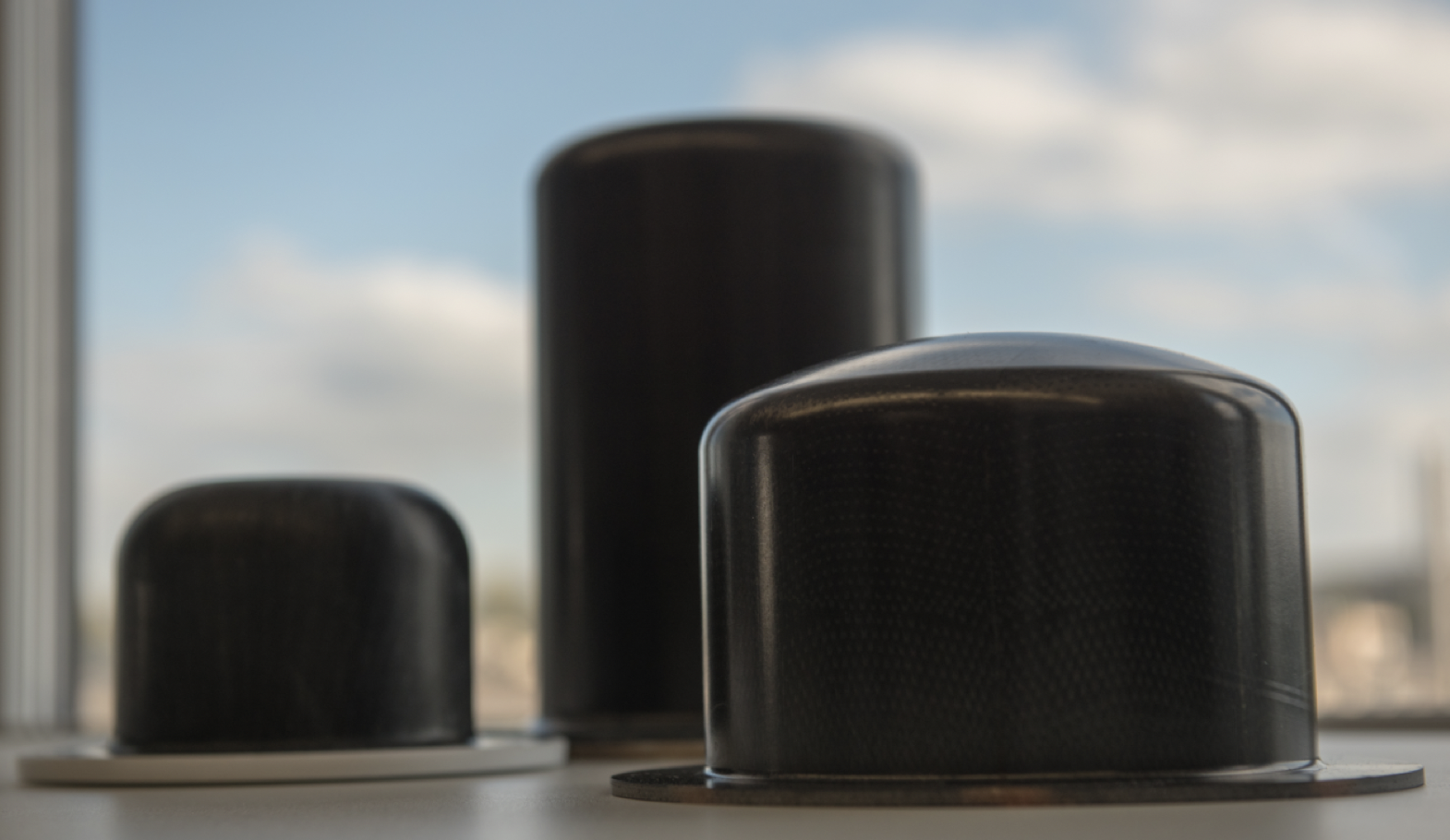

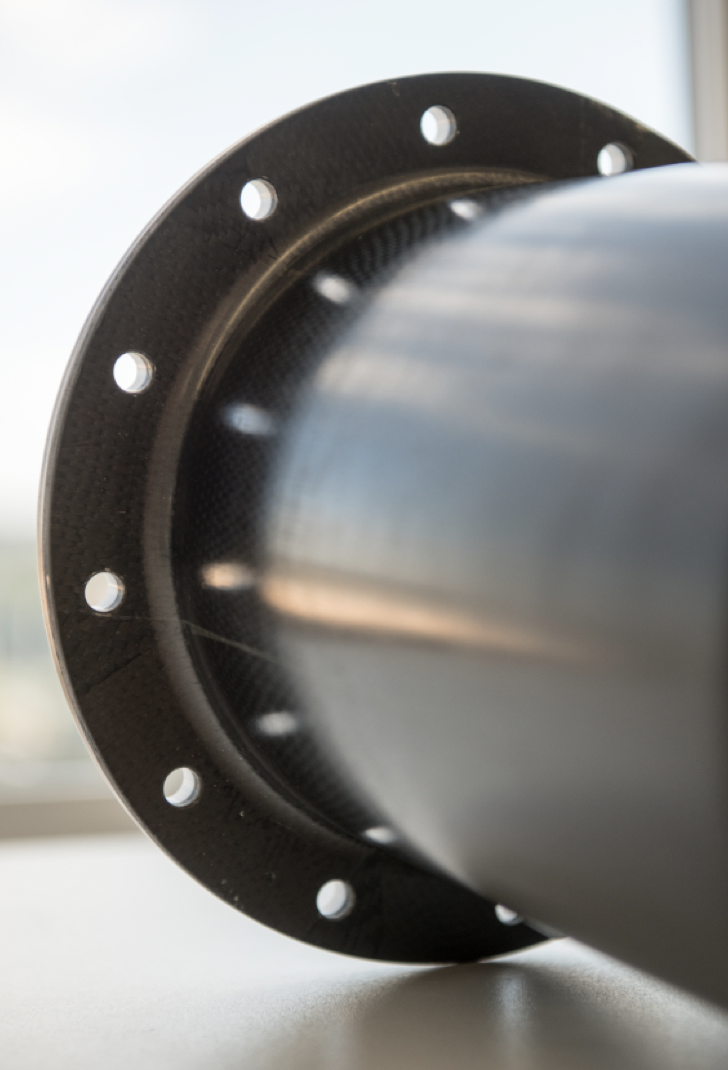

CFRP cans for high-performance pumps, electric motors & magnetic couplings

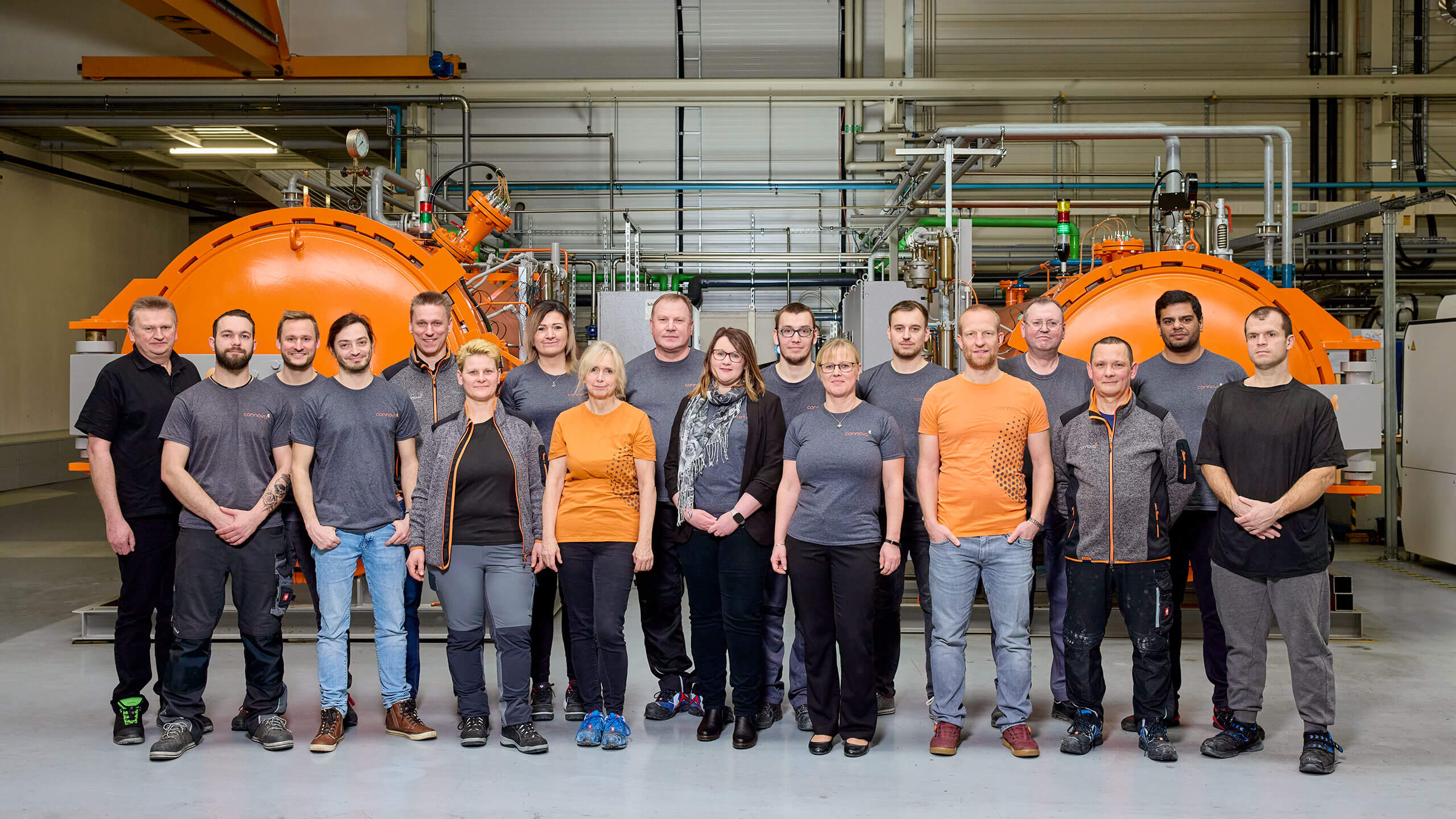

From prototypes to full series production. Increase your system efficiency by 25% – no eddy currents, optimised accuracy of fit and scalable series production for maximum performance.