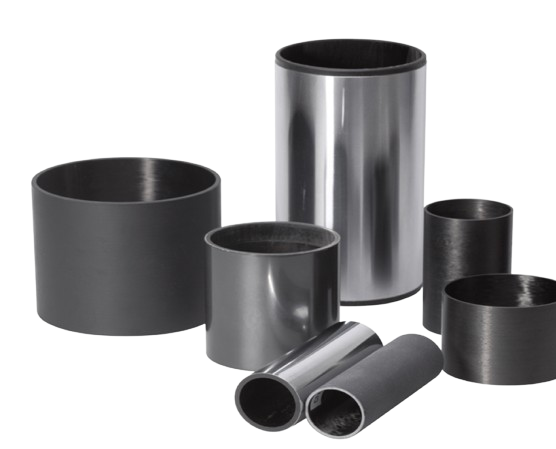

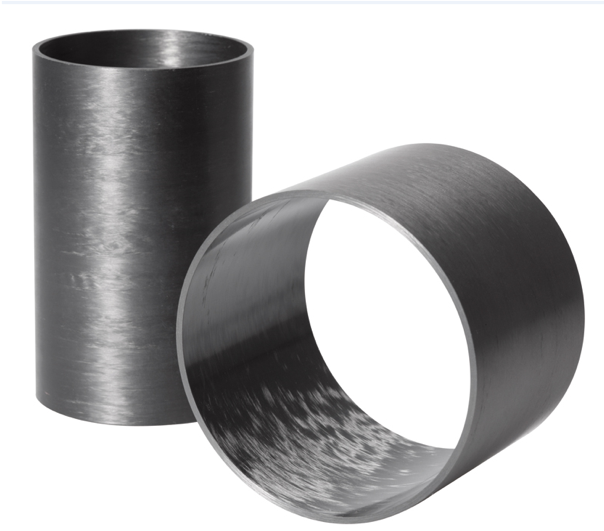

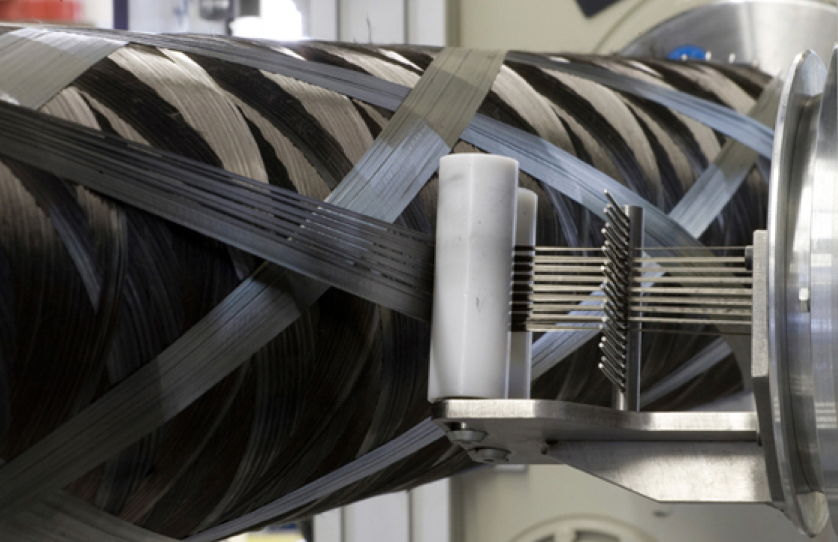

CFRP bandages and sleeves for electric drives

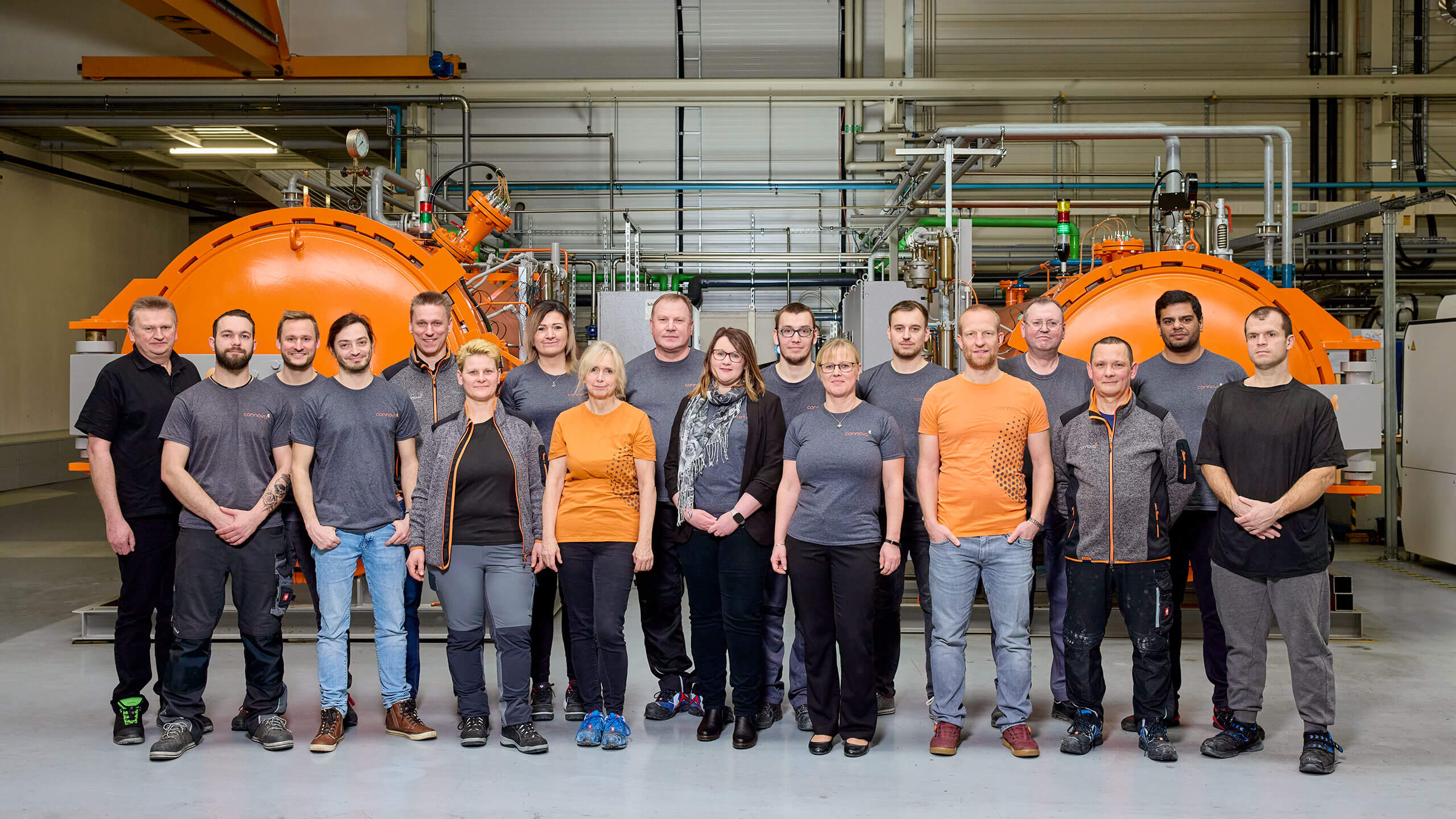

From prototypes to complete series production. We develop and manufacture CFRP sleeves and bandages made of carbon materials optimized for highest speeds – increase performance and efficiency with our scalable production.