For rotation-symmetric items – high mechanical performance, economical and scalable

Aircraft Composites

Elevating Aviation: Connova Group’s Mastery of Aircraft Composites

In the aviation industry, where every gram counts and efficiency is paramount, composite materials play a critical role. Connova Group, with over two decades of experience, has been at the forefront of advancing aircraft composite technology, offering high-performance solutions that significantly enhance the efficiency and reduce the operating costs of various aircraft types, from ultra-light experimental models to commercial airplanes and military jets.

The Role of Composites in Aviation

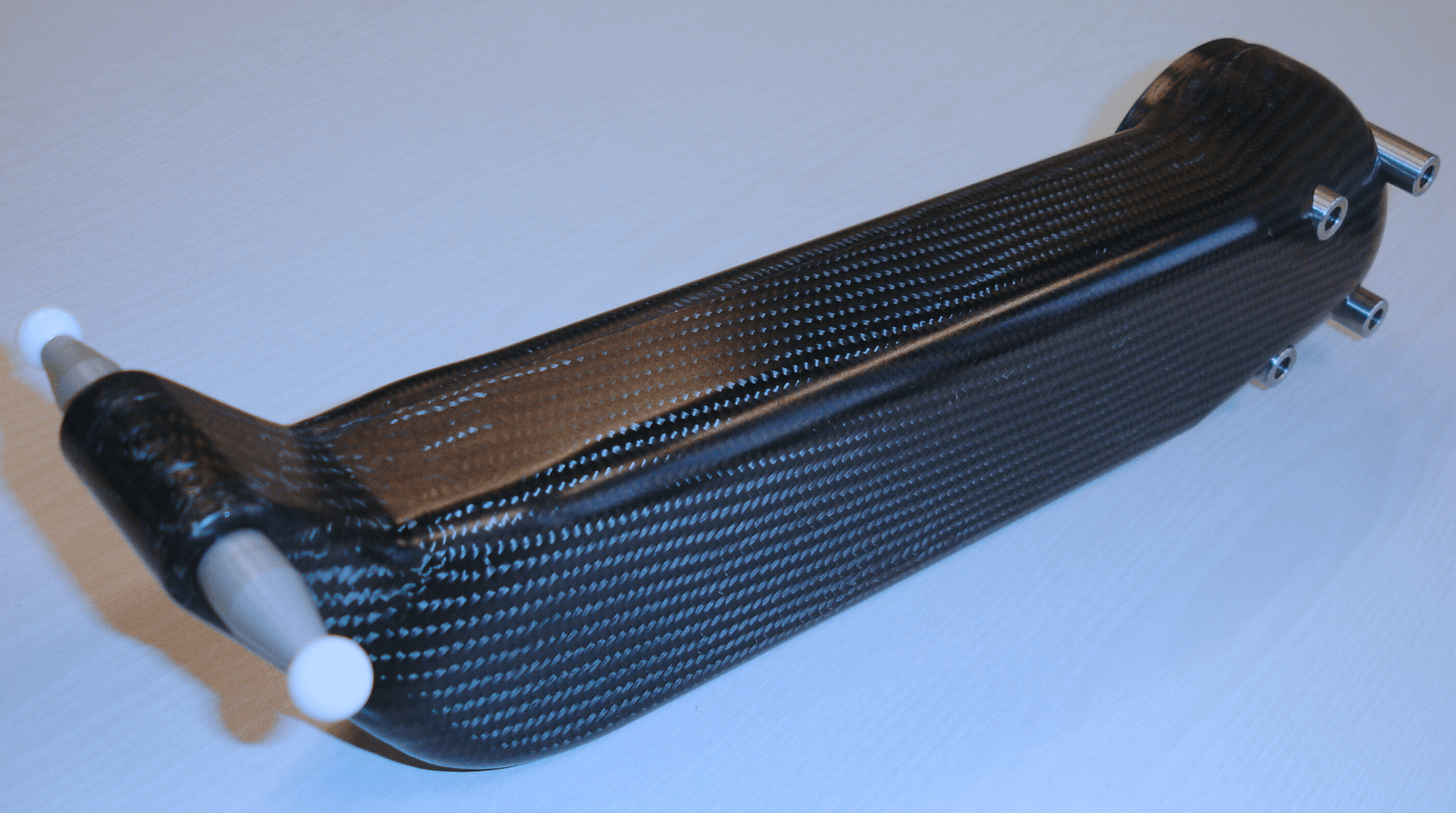

At Connova Group, the use of composites in aircraft construction is extensive, accounting for up to 60% of the material composition in some projects. These materials are selected for their exceptional strength-to-weight ratio, fatigue resistance, and versatility in engineering applications. Composites such as carbon fiber reinforced polymer (CFRP), glass fiber reinforced polymer (GFRP), and aramid fiber reinforced polymer (AFRP) are pivotal in achieving lighter, more robust, and more efficient aircraft structures.

Advantages of Connova’s Aircraft Composites

- Weight Reduction: Composites are significantly lighter than traditional materials like aluminum, leading to lower fuel consumption and increased range and payload capacities.

- Structural Integrity: Enhanced stiffness and strength allow for more durable and reliable airframes and structural components.

- Design Flexibility: The adaptability of composites enables complex shapes and designs, which are crucial for optimizing aerodynamics and integrating advanced technologies into aircraft.

- Corrosion Resistance: Unlike metal parts, composite materials do not corrode, reducing maintenance requirements and extending the lifecycle of aircraft parts.

- Thermal Resistance: Composites withstand high temperatures and exhibit minimal thermal expansion, maintaining structural integrity under varying environmental conditions.

Customized Solutions for Aviation Challenges

Connova’s approach to the aviation sector is distinguished by its commitment to customized solutions. Every component and system is tailored to meet specific performance criteria, ensuring optimal integration and functionality. From individual subassemblies to complete primary structures, Connova designs and manufactures with precision and care, meeting rigorous industry standards and client expectations.

Advanced Manufacturing Techniques

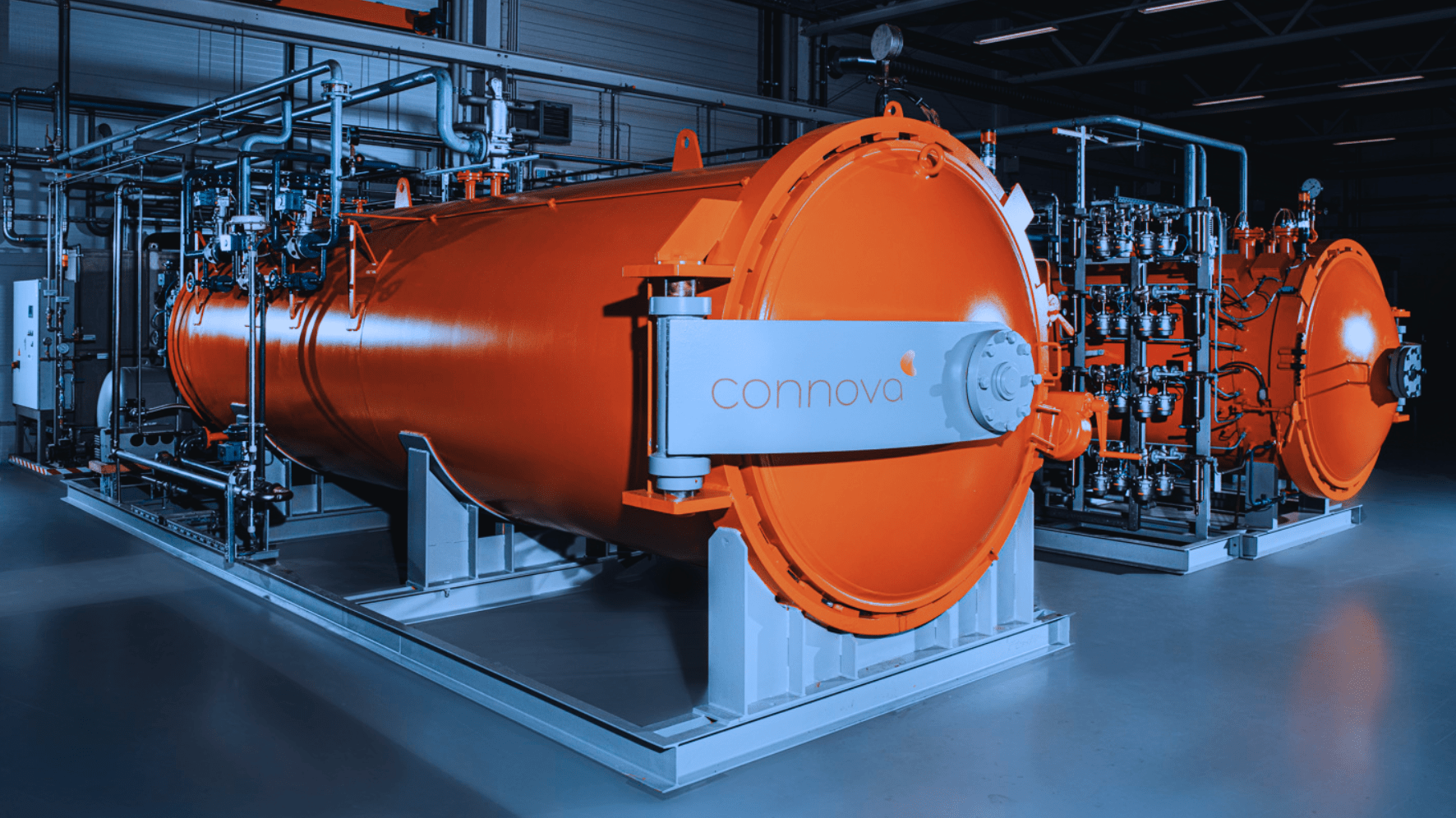

Connova’s state-of-the-art manufacturing facilities are equipped with the latest in CNC technology and autoclave systems, allowing for high-precision machining and advanced curing techniques that ensure the highest quality of composite components. The group’s engineering expertise is supported by a robust quality management system certified to EN 9100, ensuring all processes from raw material procurement to final product delivery are monitored for quality and compliance.

Key Aerospace Applications

- Aerodynamic Enhancements: Connova’s composites are integral in designing and producing airframes and components that reduce drag and improve fuel efficiency.

- Helicopter Technologies: Specialized composites for rotor blades and helicopter airframes enhance performance, safety, and manoeuvrability.

- Engine and Cockpit Components: Protecting critical systems while optimizing the control environment for pilots through the use of advanced composites.

- Fairings and Access Systems: Designed for protection and ease of maintenance, ensuring long-term functionality and aesthetic integration into overall aircraft design.

A Partner in Aerospace Innovation

Connova’s contributions to the aerospace sector extend beyond manufacturing. They are a partner in innovation, helping to develop next-generation technologies for the aviation industry. From high-performance components for traditional aircraft to pioneering materials for unmanned aerial vehicles (UAVs) and space missions, Connova is pushing the boundaries of what is possible with aircraft composites.

Connova Group not only manufactures but also collaborates closely with clients to develop and refine aerospace components, ensuring that each product not only meets but exceeds the stringent demands of modern aviation. Their extensive experience, coupled with a proactive approach to research and development, positions Connova as a leader in the field, continually contributing to safer, more efficient, and more sustainable aviation solutions.