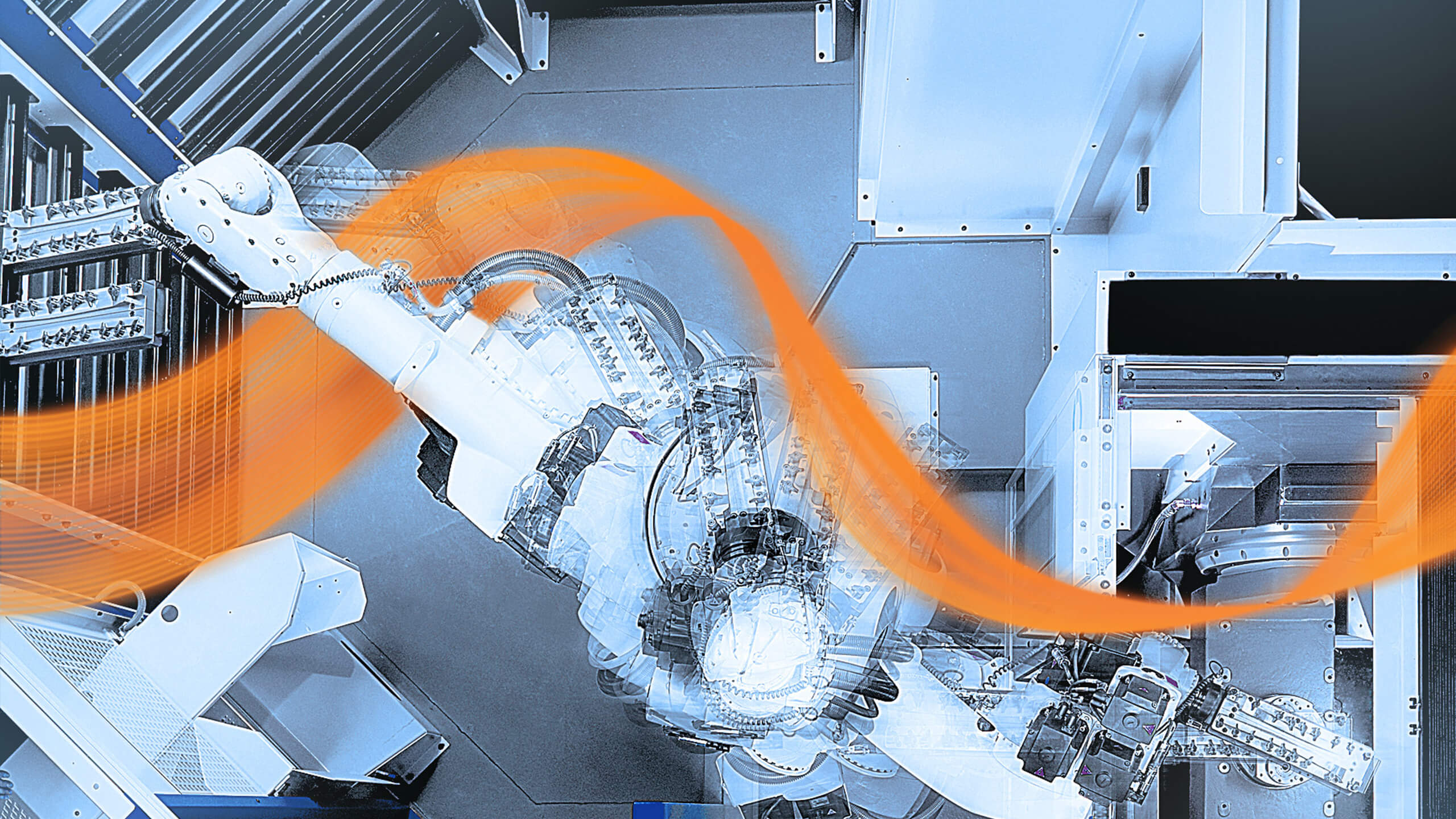

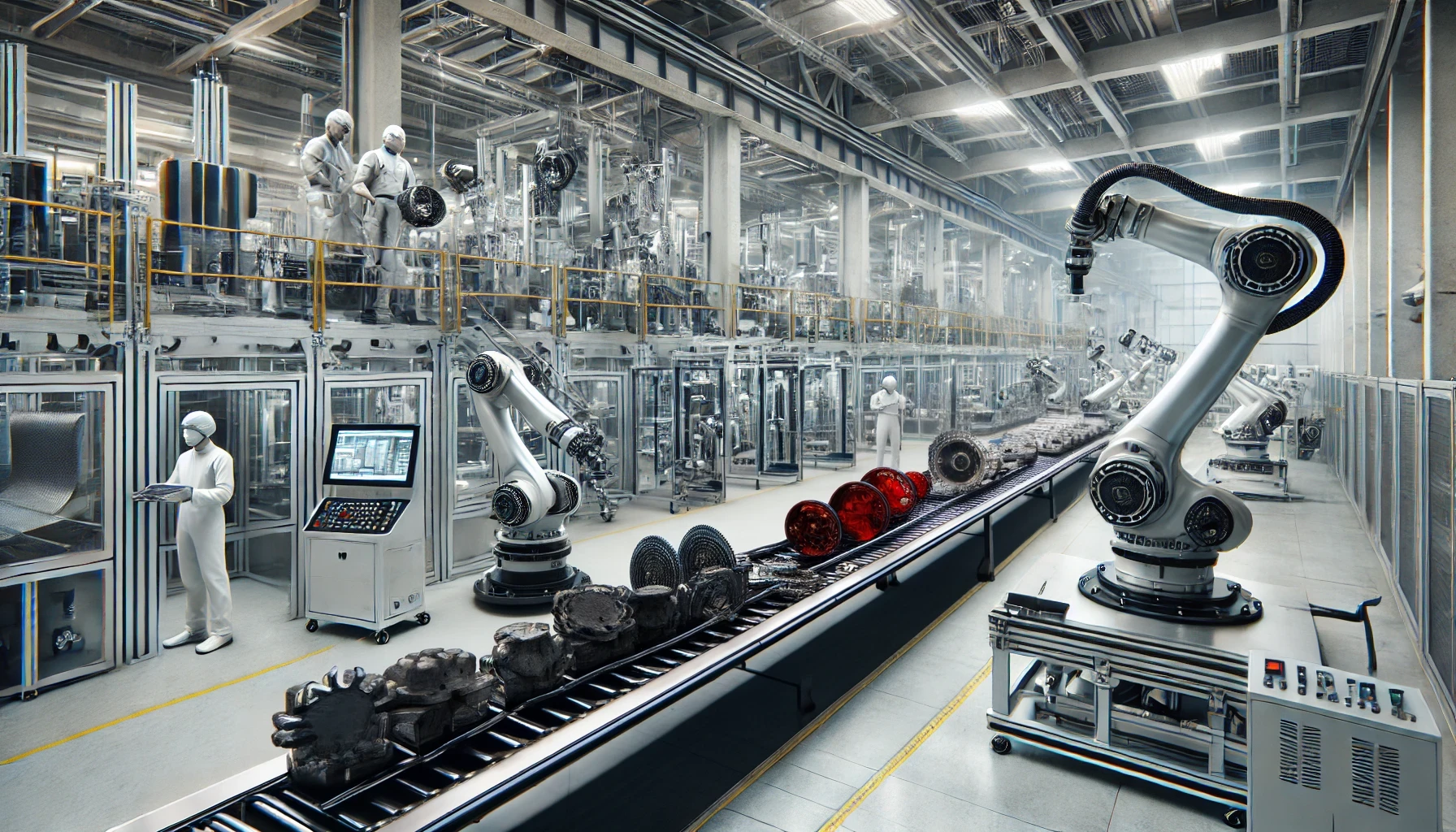

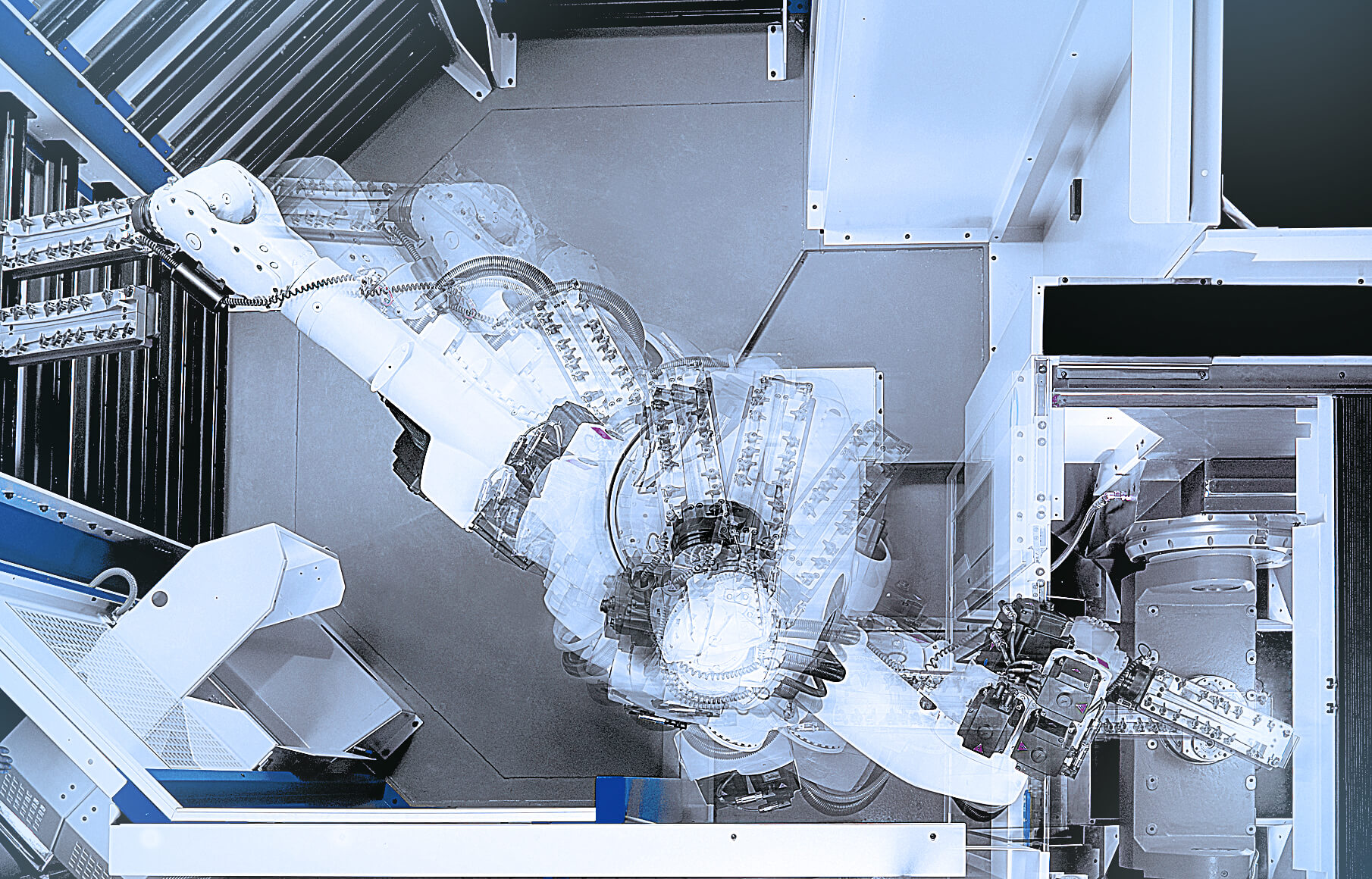

Industry and automation

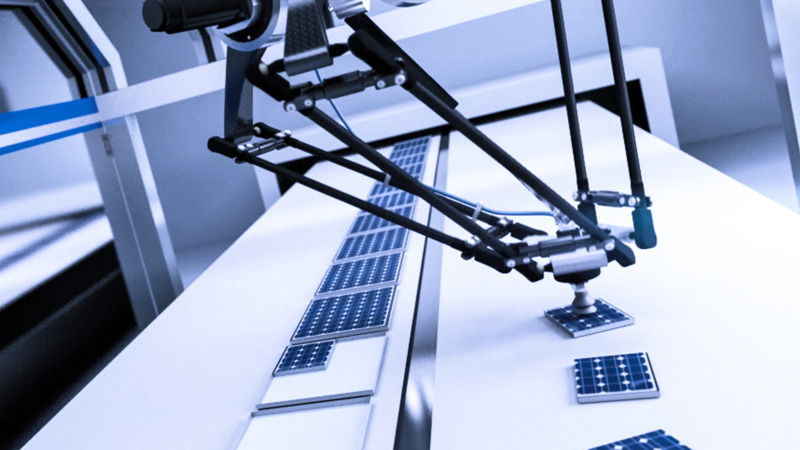

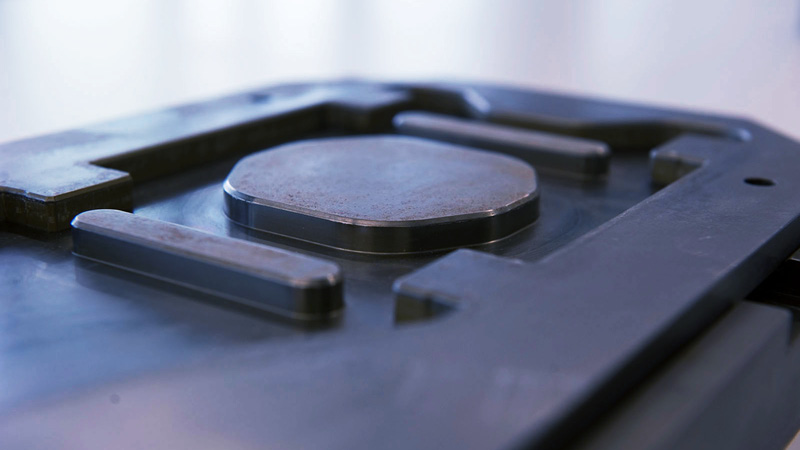

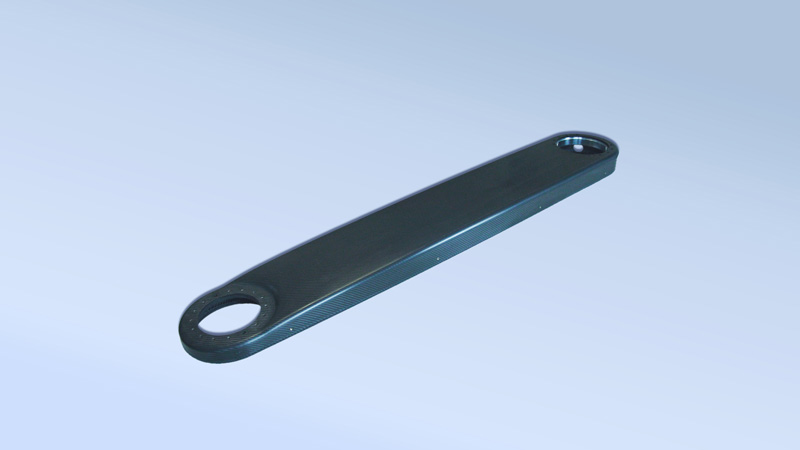

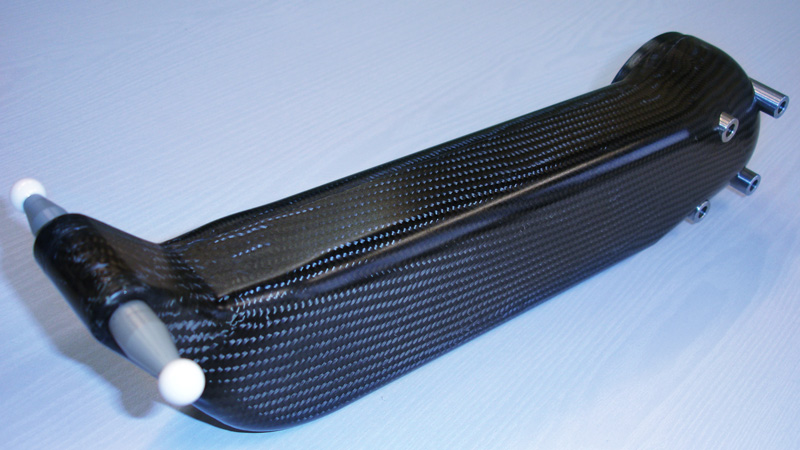

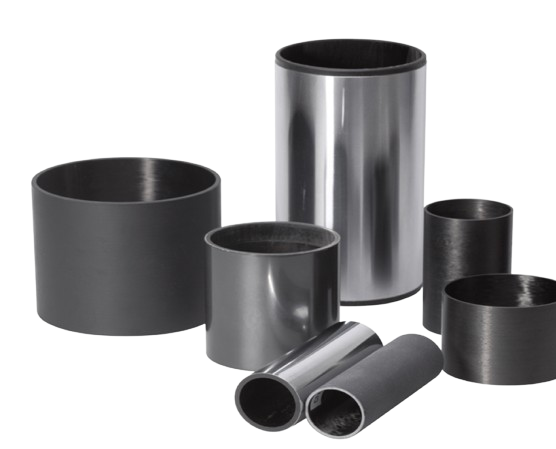

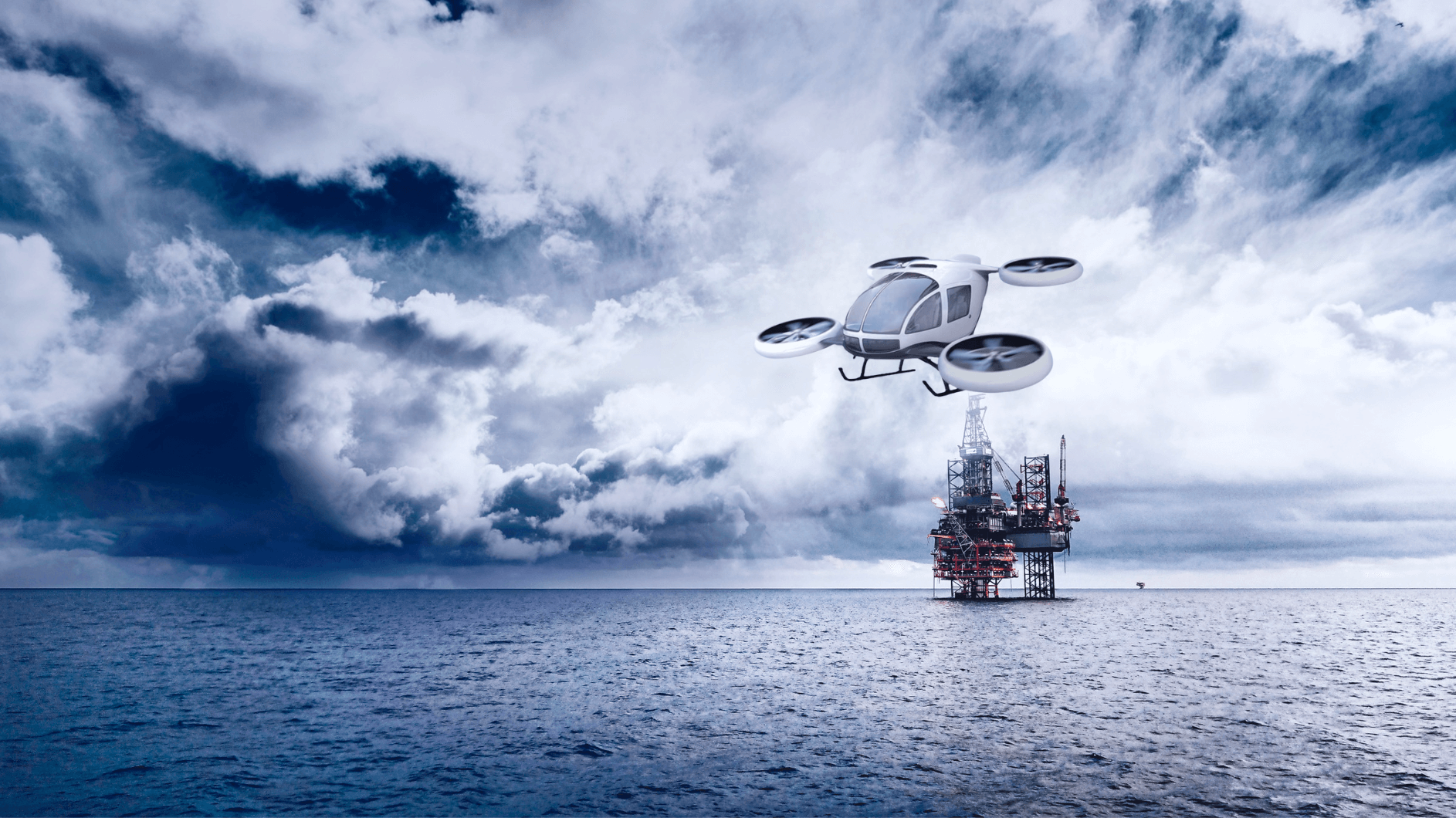

Due to their lower weight, CFRP parts and components reduce energy consumption and increase the performance of the end products. This is particularly important when it comes to maximum precision and particularly fast movements. Fatigue strength and corrosion resistance ensure a long service life and low maintenance costs. On request, we can support you right from the concept phase and offer your engineers and developers expert advice. Together with you and your team, we can also meet the highest requirements within short deadlines – individually, efficiently and economically.