KNOW-HOW

Over 20 years of experience in aviation

Over 20 years of experience in aviation

Customized solutions are our standard

Lightness and rigidity for greater efficiency in the aviation industry

The Connova Group has been active in the aviation industry for over 20 years. With our lightweight and stable composite components, we increase the efficiency and reduce the operating costs of ultra-light experimental aircraft, commercial airplanes, business jets, military jets, helicopters and drones. We have a wealth of experience in the industry and offer customized solutions.

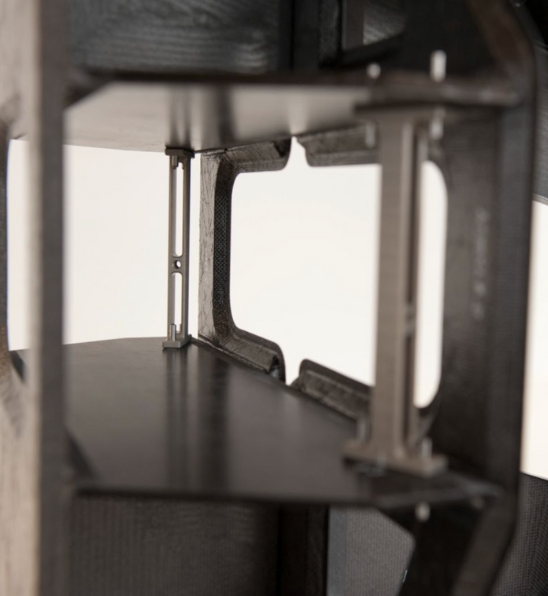

For over two decades, the Connova Group has been producing high-performance, load-bearing components and structural parts for the aviation industry. Each element and component, from individual subassemblies to the complete construction of primary structures, is designed with optimal weight efficiency, stability, and durability throughout its lifecycle. Our manufacturing methods and selection of top-quality materials guarantee peak performance, literally taking you to the skies.

From the robust airframe to the aerodynamically optimized wing, our composite materials are crucial for improving fuel efficiency and overall aircraft performance. By carefully integrating advanced materials into the fuselage, tail sections, as well as the nose and tail, we maximize aerodynamic properties and significantly reduce fuel consumption.

For the specific demands of helicopter construction, our specialized composite materials offer an unmatched combination of strength and light weight. The rotor blades we manufacture not only enhance performance and maneuverability but also set new standards for durability and reliability.

Our fairings and access systems are designed to provide maximum protection for critical components while facilitating maintenance access. Combining lightness, functionality, and aesthetic design, our doors and hatches ensure seamless integration into any aircraft design.

We offer structural components, molds, tools, prototypes and work closely with leading aerospace companies. All Connova Group production processes are 100% traceable and documented according to customer specifications.

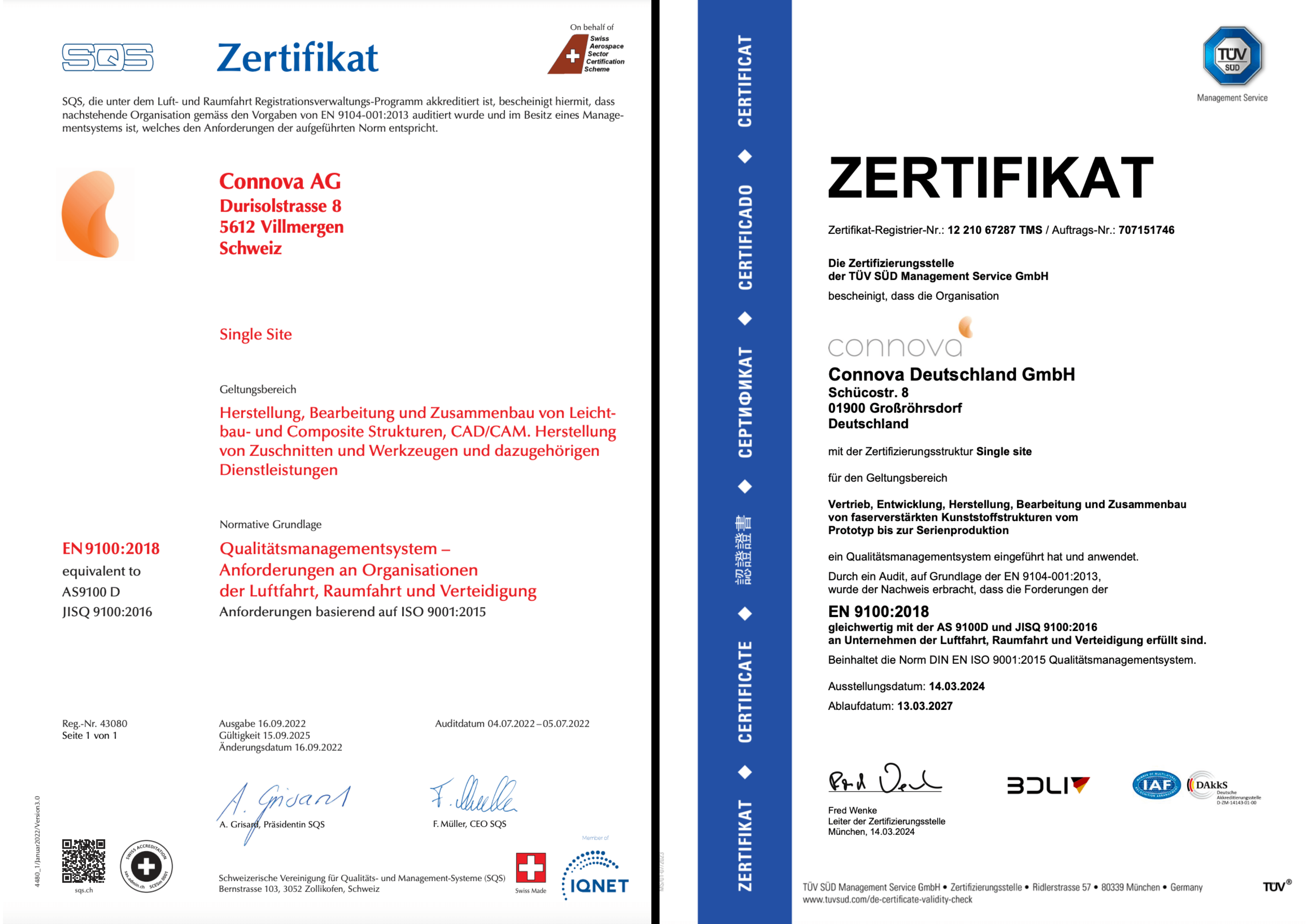

It goes without saying that our quality management system is aviation-certified in accordance with EN 9100.

As experts in composite technologies in the aviation sector, we offer a wide range of services: This includes both consulting and the development of products for the aviation industry, as well as the design and analysis of aircraft components and the improvement of aviation systems.

With their extensive experience in the production of high-performance composite materials for the aerospace sector, our specialists ensure the most efficient production method for your aerospace product, always taking into account the strictest quality criteria and guaranteed reliability in delivery.

We offer a comprehensive portfolio of CNC services specifically geared towards model making, tool making and the final machining of composite components in the aerospace industry, always with a 100% accuracy guarantee.

Our service portfolio covers all aspects of mechanical processing and support. This includes essential contributions to the production process of your aerospace composite components as well as additional support for your internal production.

We proudly maintain our demanding EN9100 certification in quality management for the aerospace industry and supplement this with the proven ISO 9001 standard. From the purchase of raw materials to the delivery of the finished product, we ensure continuously monitored and measurable quality. Our state-of-the-art testing equipment ensures compliance with the strictest industry standards. Rely on us for precision and consistent quality at every stage of your product development.

With extensive know-how from decades of experience in lightweight construction for the aviation industry, we are perfectly positioned to implement your concepts. We invite you to a professional consultation in which we will explore how we could act as your future partner. This consultation is of course non-binding and free of charge.